Introduction to Wood Simulation and Analysis in Abaqus

Wood is a complex, anisotropic material with unique mechanical properties that vary depending on grain orientation, moisture content, and other factors. Simulating and analyzing wood behavior in engineering applications requires specialized tools and methodologies. Abaqus, a powerful finite element analysis (FEA) software, is widely used to simulate the mechanical response of materials, including wood

Material Modeling for Wood

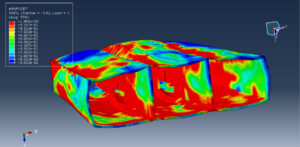

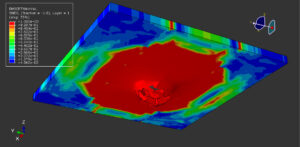

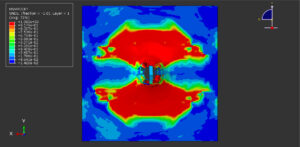

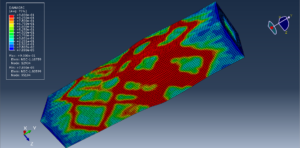

Anisotropic Elasticity: Wood exhibits different mechanical properties along its longitudinal, radial, and tangential directions. In Abaqus, wood can be modeled as an orthotropic material, where the elastic properties are defined for each principal direction

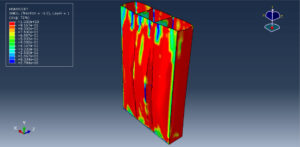

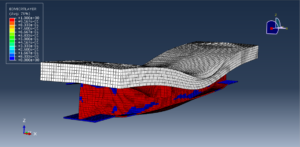

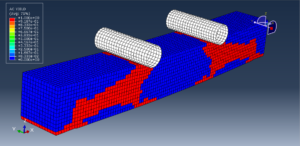

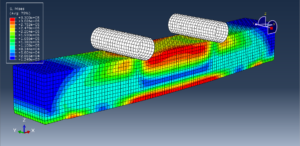

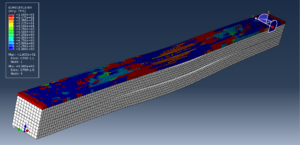

Plasticity and Failure: Wood can undergo plastic deformation and failure under stress. Abaqus allows for the incorporation of plasticity models and failure criteria, such as maximum stress or strain-based failure, to simulate wood behavior under extreme loading conditions

Moisture and Temperature Effects: Wood properties are highly sensitive to moisture content and temperature. Abaqus can model these effects using coupled thermal-mechanical analyses or user-defined material subroutines (UMAT)

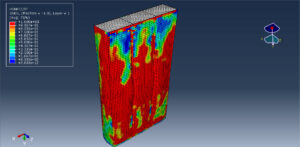

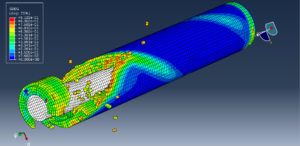

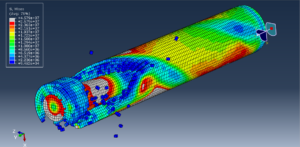

The present package considers the elastic, plastic, and damage behavior of wood. Wood’s mechanical properties depend on the grain orientation. In Abaqus, local material orientations can be assigned to elements to align with the grain direction, ensuring accurate simulation of anisotropic behavior

Types of Analysis

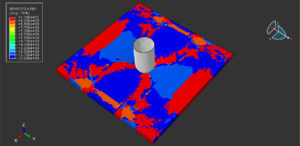

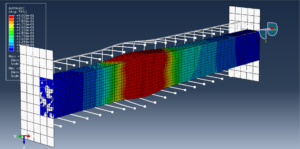

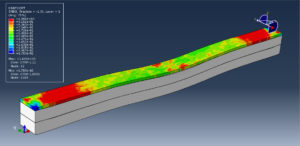

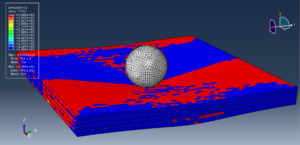

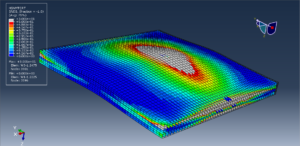

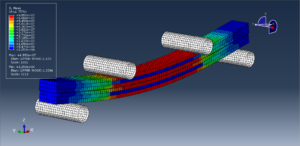

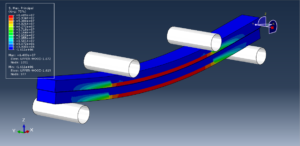

Static Analysis: Used to simulate the response of wood structures under static loads, such as bending, compression, or tension

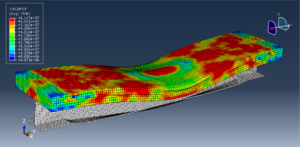

Dynamic Analysis: For simulating time-dependent loads, such as impact or vibration, Abaqus provides explicit and implicit dynamic solvers

Nonlinear Analysis: Wood often exhibits nonlinear behavior due to its anisotropic nature and complex failure modes. Abaqus supports geometric and material nonlinearities

Buckling Analysis: To predict the buckling behavior of wooden structures under compressive loads

Moisture Diffusion Analysis: To study the effects of moisture absorption or desorption on wood properties

Failure and Damage Modeling

Abaqus provides built-in damage models, such as Hashin’s criterion or user-defined damage initiation and evolution laws, to simulate progressive failure in wood

Crack propagation in wood can be modeled using techniques like the Extended Finite Element Method (XFEM) or cohesive zone modeling (CZM)

Applications

Structural Engineering: Simulating wooden beams, columns, and frames under various loading conditions

Furniture Design: Analyzing the strength and durability of wooden furniture components

Wood Composites: Modeling engineered wood products like plywood, laminated veneer lumber (LVL), or cross-laminated timber (CLT)

Biomechanics: Studying the mechanical behavior of wood in natural structures, such as trees or plant stems

Challenges in Wood Simulation

Material Variability: Wood properties can vary significantly between species and even within the same piece of wood

Complex Failure Modes: Wood can fail in brittle, ductile, or mixed modes, requiring advanced modeling techniques

Moisture and Environmental Effects: Accurately capturing the influence of environmental conditions on wood behavior can be challenging

By leveraging Abaqus’s advanced capabilities, engineers and researchers can gain valuable insights into the behavior of wood and optimize designs for performance, durability, and safety.

The package contains Twelve separate tutorials, each tutorial includes cae, inp, code, paper, reference of the materials, and step-by-step English video. You can check the titles of the tutorials below

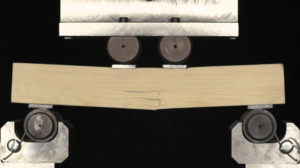

K) Simulation dynamic four points bending of the timber wood beam reinforced with CFRP rod and Glue in AbaqusM) Simulation Wood-Glue-CFRP beam under dynamic four points bending test in Abaqus

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials