Ultra-High-Performance Fiber-Reinforced Concrete (UHPFRC) in Abaqus

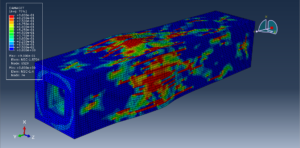

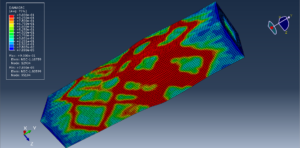

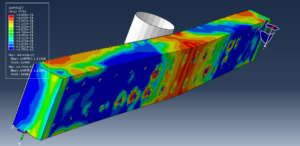

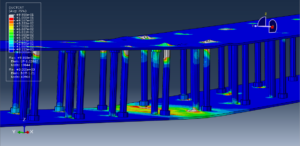

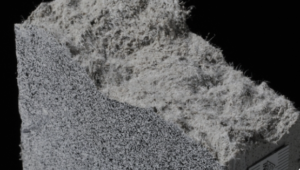

Ultra-high-performance fiber-reinforced Concrete (UHPFRC) is an advanced construction material characterized by its exceptional mechanical properties, including high compressive strength, tensile strength, and durability. UHPFRC is typically composed of a dense matrix of fine particles, high-strength cement, and steel or synthetic fibers, which enhance its toughness and crack resistance. These properties make UHPFRC suitable for demanding structural applications where high performance and longevity are critical. When modeling UHPFRC in Abaqus, a finite element analysis (FEA) software, it is essential to accurately capture its unique material behavior

Key Features of UHPFRC in Abaqus Modeling

Material Properties

High Compressive Strength: UHPFRC can have compressive strengths exceeding 150 MPa, requiring appropriate material definitions in Abaqus

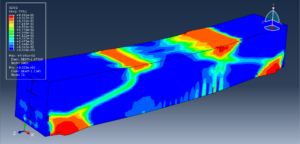

ensile Behavior: UHPFRC exhibits strain-hardening behavior under tension due to fiber reinforcement, which must be modeled using a suitable constitutive law

Fiber Contribution: The fibers in UHPFRC provide post-cracking ductility, which can be simulated using smeared crack models or cohesive zone models

Constitutive Models

Elastic-Plastic Model: For simplified analysis, UHPFRC can be modeled as an elastic-plastic material with defined yield criteria

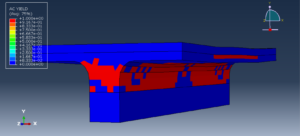

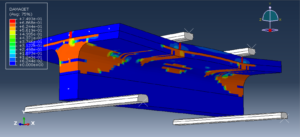

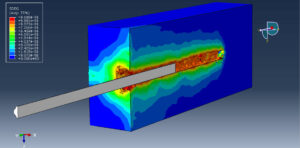

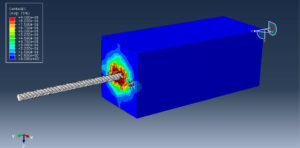

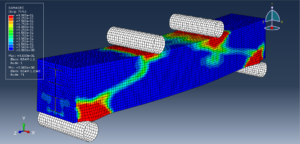

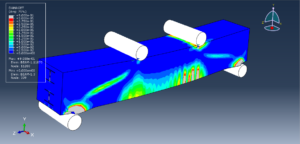

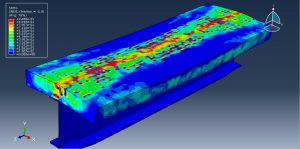

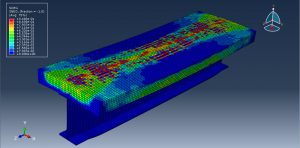

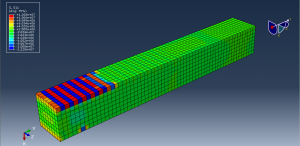

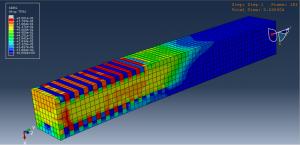

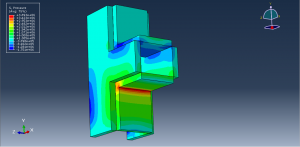

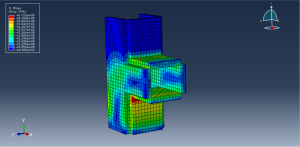

Damage Plasticity Model: The Concrete Damaged Plasticity (CDP) model in Abaqus is commonly used to simulate the nonlinear behavior of UHPFRC, including tension softening and compression hardening

Cohesive Zone Model: For detailed fracture analysis, cohesive elements can be used to model crack propagation and fiber bridging effects

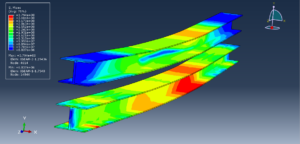

Fiber Orientation and Distribution: The orientation and distribution of fibers significantly influence the mechanical behavior of UHPFRC. In Abaqus, this can be modeled using anisotropic material properties or by explicitly defining fiber orientations in the mesh

Ultra-high-performance fiber-reinforced Concrete (UHPFRC) offers numerous advantages when used in structural applications, making it a highly desirable material for modern engineering projects. Below are the key advantages of using UHPFRC in structures

Exceptional Mechanical Properties

High Compressive Strength: UHPFRC typically has compressive strengths exceeding ۱۵۰ MPa (and can reach up to ۲۵۰ MPa or more), which is significantly higher than conventional concrete. This allows for the design of slimmer and lighter structural elements

High Tensile Strength: Unlike conventional concrete, UHPFRC exhibits tensile strength due to the inclusion of fibers, which helps resist cracking and improves structural integrity

Enhanced Ductility: The fibers in UHPFRC provide post-cracking ductility, enabling the material to withstand large deformations without sudden failure

Superior Durability

Resistance to Environmental Degradation: UHPFRC has a very dense microstructure, which makes it highly resistant to water penetration, chemical attack, and corrosion of embedded reinforcement

Long Service Life: Structures made with UHPFRC have a longer lifespan due to their resistance to weathering, freeze-thaw cycles, and abrasion

Improved Crack Control: The fibers in UHPFRC act as micro-reinforcement, bridging cracks and preventing them from propagating. This results in better crack control and improved structural performance under service loads

Applications of UHPFRC in Abaqus

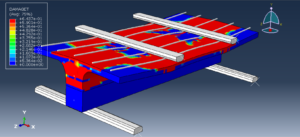

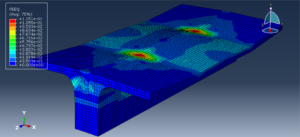

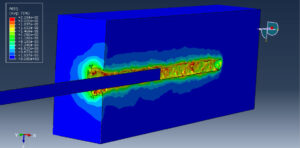

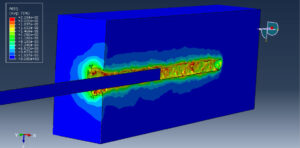

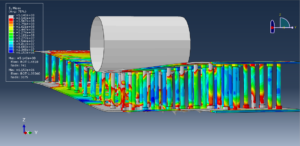

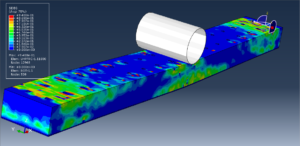

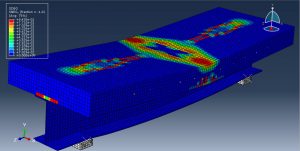

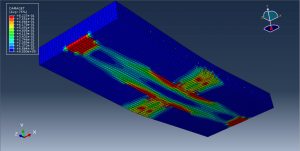

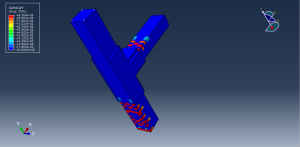

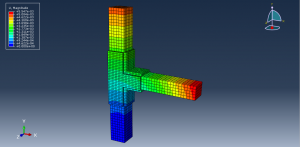

Bridge Girders and Decks: Simulating the performance of UHPFRC in bridge elements under heavy loads

Seismic Retrofitting: Modeling UHPFRC as a strengthening material for existing structures

Blast and Impact Resistance: Analyzing UHPFRC structures under extreme loading conditions

Thin Shells and Architectural Elements: Studying the behavior of lightweight UHPFR Components

By accurately modeling UHPFRC in Abaqus, engineers can predict its structural performance and optimize designs for a wide range of applications. The advanced material properties of UHPFRC, combined with the powerful simulation capabilities of Abaqus, enable the development of innovative and resilient structures.

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials