Introduction to Ultra-High-Performance Concrete (UHPC) in Abaqus

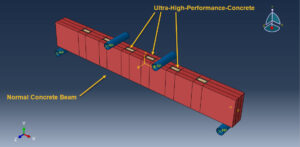

Ultra-high-performance concrete (UHPC) is an advanced cementitious material characterized by its exceptional strength, durability, and ductility. It typically has a compressive strength exceeding 150 MPa and can reach up to 250 MPa or higher, along with superior tensile strength and resistance to environmental degradation. UHPC is widely used in infrastructure projects, such as bridges, high-rise buildings, and protective structures, due to its ability to withstand extreme loads and harsh conditions. Ultra-high-performance concrete (UHPC) offers numerous advantages in structural applications due to its exceptional mechanical and durability properties. Below are the key advantages of using UHPC in structures:

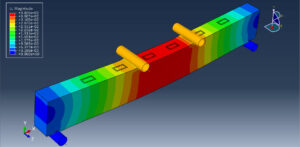

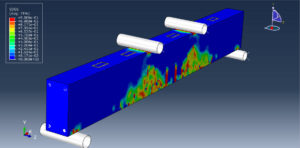

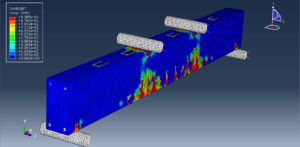

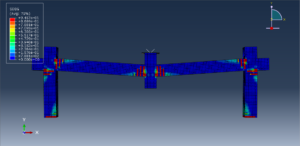

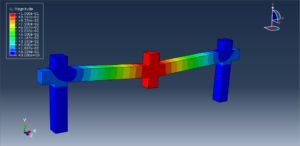

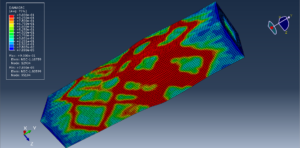

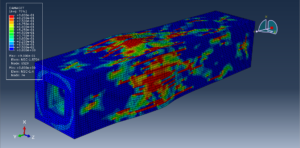

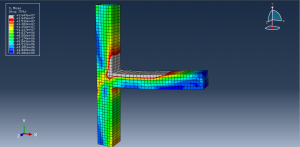

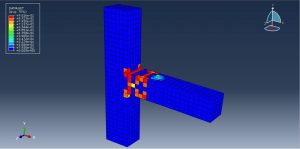

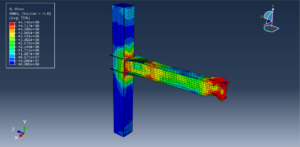

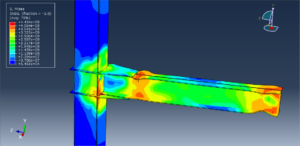

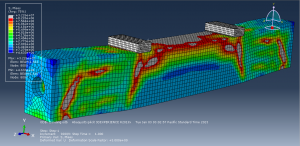

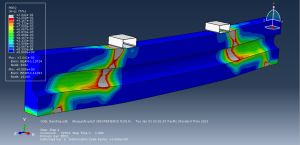

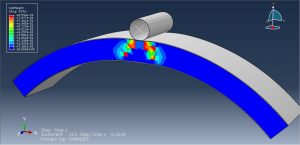

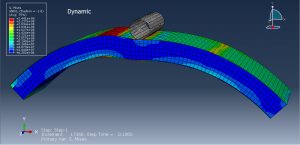

When modeling UHPC in Abaqus, a finite element analysis (FEA) software, it is essential to capture its unique material properties and behavior accurately

Material Properties of UHPC

High Compressive Strength: UHPC has a compressive strength significantly higher than that of conventional concrete. This must be defined in the material model

Tensile Behavior: UHPC exhibits strain-hardening behavior under tension, which is different from the brittle failure of normal concrete

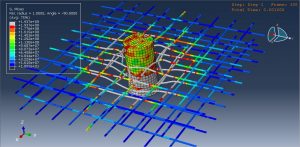

Fiber Reinforcement: UHPC often contains steel or synthetic fibers to enhance its tensile strength and ductility. The fiber-matrix interaction must be considered in the model

Elastic Modulus: UHPC has a high elastic modulus, typically in the range of 40–۶۰ GPa

Density: The density of UHPC is slightly higher than conventional concrete due to its dense microstructure

Material Modeling in Abaqus

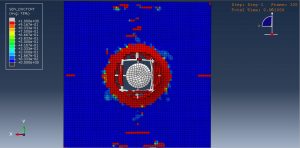

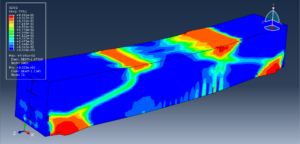

Concrete Damage Plasticity (CDP) Model: This is the most commonly used material model for UHPC in Abaqus. It accounts for both compressive and tensile damage, as well as plasticity effects

Define the stress-strain curves for compression and tension

Specify damage parameters (dc for compression and dt for tension) to capture the degradation of stiffness

Enhanced Durability

Low Permeability: UHPC has a very dense microstructure, which makes it nearly impermeable to water and aggressive chemicals. This significantly improves its resistance to

Chloride Ion Penetration: Reduces the risk of corrosion in reinforced structures

Freeze-Thaw Cycles: Enhances performance in cold climates

Chemical Attack: Resists acids, sulfates, and other corrosive substances

Long Service Life: Structures made with UHPC have a longer lifespan due to reduced degradation over time

Superior Ductility

UHPC exhibits strain-hardening behavior under tension, meaning it can undergo significant deformation before failure. This ductility is achieved through the inclusion of steel or synthetic fibers, which bridge microcracks and prevent sudden brittle failure

This property is particularly beneficial in seismic zones, where structures need to withstand large deformations without collapsing

Reduced Structural Weight

The high strength of UHPC allows for the design of thinner and lighter structural elements (e.g.,beams, slabs, and columns) without compromising load-bearing capacity. This leads to

Reduced Dead Load: Lower self-weight of the structure

Smaller Foundations: Savings in foundation design and construction costs

Longer Spans: Enables the construction of longer-span bridges and roofs

Improved Crack Resistance

The inclusion of fibers in UHPC significantly improves its crack resistance and post-cracking behavior. Cracks in UHPC are finer and more distributed, which helps maintain structural integrity and load-bearing capacity even after cracking

Sustainability

Although UHPC has a higher initial cost, its long service life and reduced maintenance requirements make it a sustainable choice in the long term

The use of UHPC can reduce material consumption and construction waste due to its high efficiency and durability

Challenges in Modeling UHPC

Complex Material Behavior: UHPC’s strain-hardening and damage evolution require accurate

Computational Cost: The fine mesh and nonlinear analysis can be computationally expensive

Fiber-Matrix Interaction: Modeling the interaction between fibers and the UHPC matrix requires advanced techniques

Applications of UHPC in Abaqus

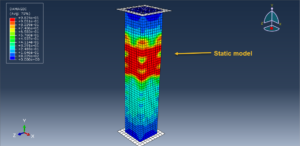

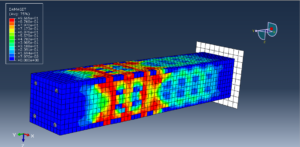

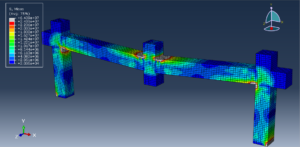

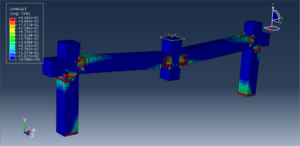

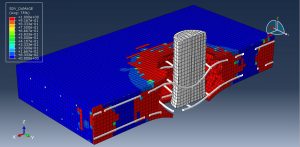

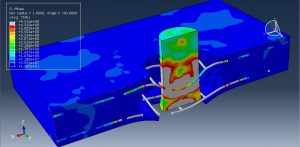

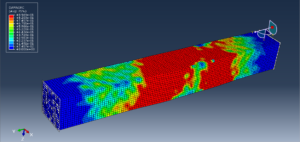

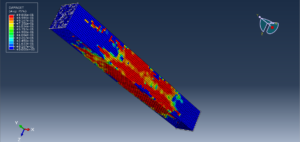

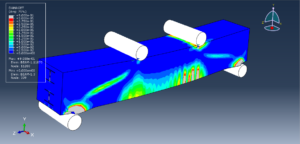

Structural Analysis: Simulating the behavior of UHPC beams, columns, and slabs under various loading conditions

Impact and Blast Analysis: Evaluating the performance of UHPC structures under extreme dynamic loads

Durability Studies: Assessing the long-term performance of UHPC in aggressive environments

By accurately modeling UHPC in Abaqus, engineers can predict its structural performance and optimize designs for safety and efficiency. Proper calibration of material properties and careful consideration of UHPC’s unique characteristics are crucial for reliable simulations. In summary, UHPC offers a combination of strength, durability, and versatility that makes it an ideal material for modern structural engineering challenges. Its use can lead to safer, more efficient, and longer-lasting structures

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials