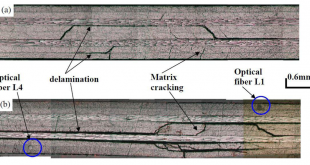

The use of composite materials in critical aerospace structures is still limited by their relatively weak mechanical response to impact events. In addition, composite laminates subjected to low velocity impact such as dropped tools or vehicle impact, exhibit significant internal damage and delamination, with little indication on the impact surface ...

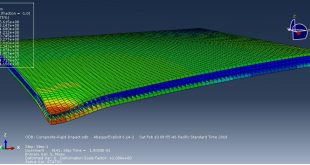

ادامه نوشته »Simulation low velocity impact to the hybrid core sandwich structure in Abaqus

core sandwich structures are fabricated with Epoxy-Glass fiber reinforced face sheets and aluminum alloy cores.This lightweight design concept enables sandwich structures to maximize their specific bending stiffness/strength and improve their energy absorption capability. To model composite behavior under impact Hashin’s damage criterion has been used.Explicit procedure is appropriate for this ...

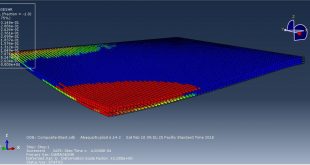

ادامه نوشته »Simulation air blast explosion over sandwich panel(AL-Epoxy-Glass) in Abaqus

In this video air blast explosion over a sandwich panel made of Aluminium and Epoxy Glass layers has been simulated. For modeling blast effect CONWEP procedure is appropriate . Aluminium is modeled as three dimensional part and for modeling it’s behavior under blast load ductile damage with Johnson-Cook plasticity and ...

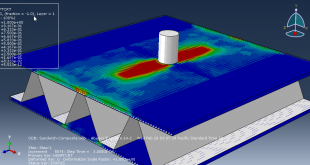

ادامه نوشته »Simulation Rigid body impact to the sandwich panel(Al-Epoxy-Glass) in Abaqus

In this video rigid impact to the sandwich panel made of Aluminium and Epoxy-Glass layers has been investigated. All parts are modeled as three dimensional. To model aluminium behavior under the impact Johnson-Cook plasticity with Ductile Damage and for composite Elastic and Hashin’s Damage has been used.To create a better ...

ادامه نوشته » Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials