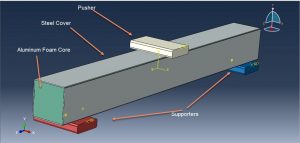

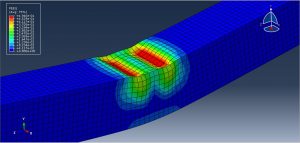

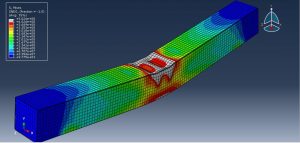

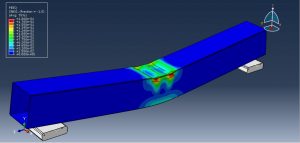

In this tutorial, the simulation three points bending of a steel beam with an aluminum foam core in Abaqus has been investigated. The steel box beam is modeled as a three-dimensional shell part. The aluminum foam is modeled as a three-dimensional solid part. The shell rigid body is created as a force body and boundary zone. You can see a figure of the assemble parts at below

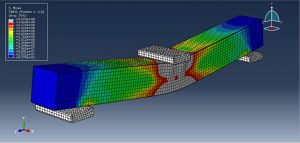

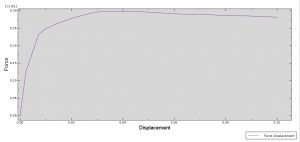

Metal foams structures, due to its impact absorbing properties could be considered as passive safety systems in transportations which still have a great potential for development as a way to reduce deaths and injuries, which is also associated to the economic costs and social impacts associated with this problem. On the other hand, from an environmental standpoint, the use of advanced composite materials to this end can also represent an optimized level of energy efficiency. The impact energy absorption, with the use of a well-designed lightweight protection system, is directly related to the thermal efficiency and consumption of the engines, thus leading to a lower level of greenhouse gases sent to the atmosphere. For the steel box beam, the elastic-plastic material model with ductile damage criterion to predict damage initiation under bending is used. The aluminum foam is modeled as an elastic material with Crushable foam plasticity which is available in Abaqus CAE. The general static step is appropriate for this type of analysis. The surface to surface contact algorithm with contact property is used to model interactions between rigid bodies and steel box. The perfect contact is assumed between the steel box surfaces and aluminum foam. The fixed boundary condition is assigned to the two bottom rigid bodies and displacement to the top rigid body. The mesh should be fine to obtain good results

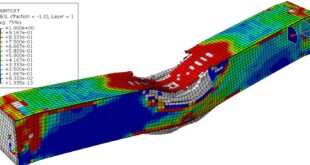

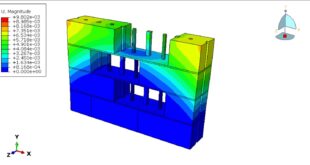

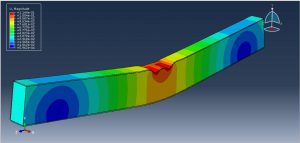

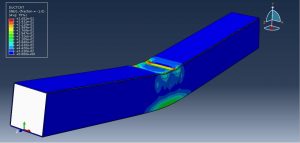

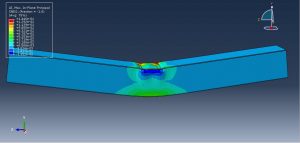

After the simulation, all results such as stress, strain, ductile damage, force-displacement diagram and others are achievable. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials