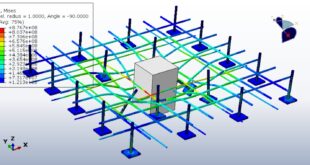

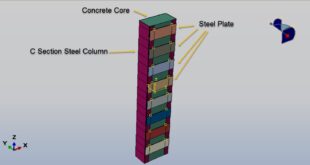

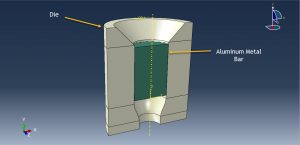

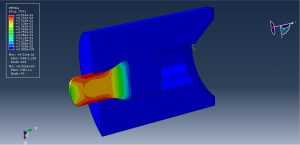

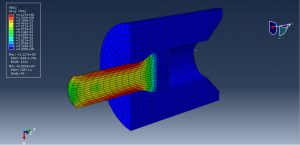

In this tutorial, the Simulation three-dimensional cold extrusion process of an aluminum rod in Abaqus has been done. The aluminum rod and die are modeled as three-dimensional solid part. You can see a figure of the assembled parts below

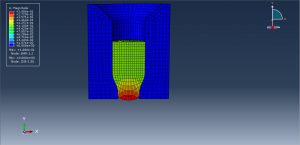

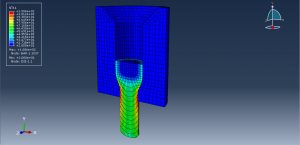

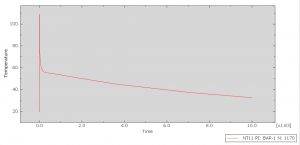

The aluminum material is considered as a elastic material with plastic data depends in temperature. The conductivity, specific heat, expansion coefficient, and inelastic heat fraction is used because of the thermally coupled step which is used. A fully coupled temperature-displacement analysis is performed with the die kept at a constant temperature. In addition, an adiabatic analysis is presented using Abaqus/Standard without accounting for frictional heat generation. Both the node-to-surface (default) and the surface-to-surface contact formulations in Abaqus/Standard are presented Four steps are used in this tutorial. In the first step the contact establishment is considered. In the second step the extrusion process is done. In the third step the contacts are removed. In the fourth step the cooling process is applied. The convection as a surface file condition is selected for the metal bar puter surfaces. The surface to surface contact with friction and heat generation as a property is selected. The fixed boundary condition is assigned to the die and displacement to the bar. The mesh should be fine to achieve the correct results

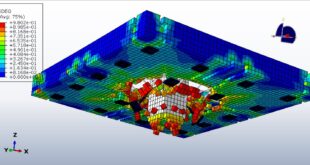

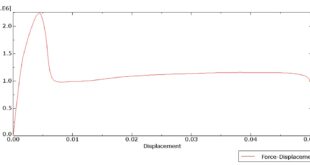

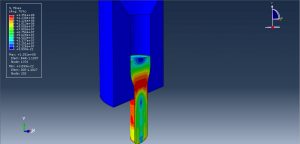

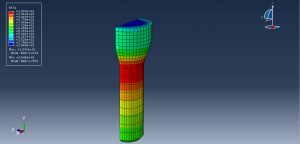

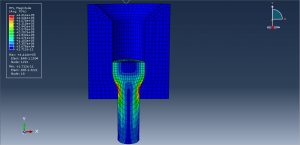

After the simulation all results such as stress, plastic strain, temperature, and … are available. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Two Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials