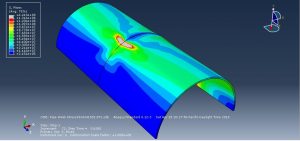

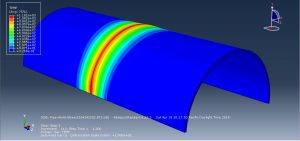

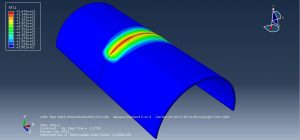

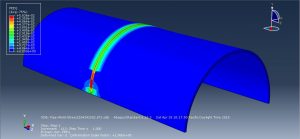

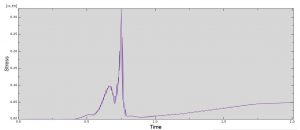

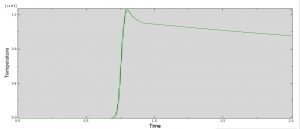

Arc welding is one of several fusion processes for joining metals. By applying intense heat, metal at the joint between two parts is melted and caused to intermix – directly, or more commonly, with an intermediate molten filler metal. Upon cooling and solidification, a metallurgical bond is created. Since the joining is an intermixture of metals, the final weldment potentially has the same strength properties as the metal of the parts. This is in sharp contrast to non-fusion processes of joining (i.e. soldering, brazing etc.) in which the mechanical and physical properties of the base materials cannot be duplicated at the joint.In this tutorial steel material for pipes and DFLUX subroutine to create non uniform heat distribution has used. All material data are depend on temperature and for analysis weld process Displacement Couple with Temperature step was used. You can see some figures of this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Eight Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials