In this tutorial Simulation steel-Silicon Carbide-Steel trilayers subject to ballistic impact in Abaqus has been studied.Armor systems containing ceramic components can significantly outperform monolithic metals of equivalent areal density. Their performance depends on not only the intrinsic properties of the constituent materials but also on the relative amounts of ceramic and metal and their spatial arrangement. For applications involving military ground vehicles, the armors must be designed to protect against a range of projectile threats and be lightweight, to maintain vehicle maneuverability, load-carrying capacity and fuel efficiency. In the present study, numerical simulations with established constitutive laws for the constituent materials are used to investigate the effects of design on ballistic performance of model composite armors comprising layers of ceramic and metal. Comparisons are made on the basis of equivalent areal density

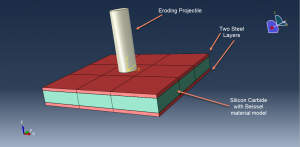

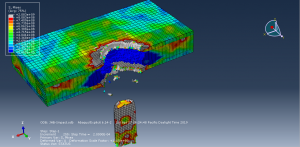

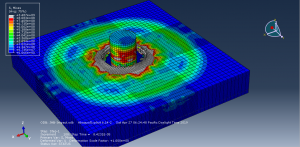

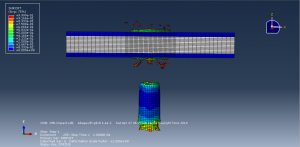

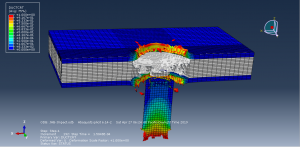

Two steel plates and ceramic are modeled as three dimensional parts. The projectile is modeled as cylindrical part.You can see a figure of the assembled parts

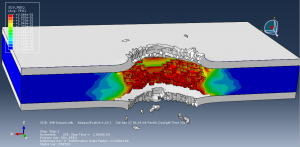

To model steel behavior for plates and projectile elastic.plastic data depend on strain rate,ductile damage with evolution and shear damage has been used. To model silicon carbide behavior under high strain rate deformation Johnson Holmquist Beissel has been used.he JHB model consists of three main components: a representation of the deviatoric strength of the intact and fractured material in the form of a pressure-dependent yield surface, a damage model that transitions the material from the intact state to a fractured state, and an equation of state (EOS) for the pressure-density relation that can include dilation (or bulking) effects as well as a phase change

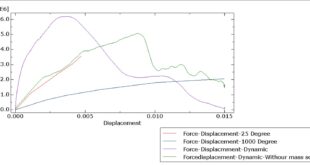

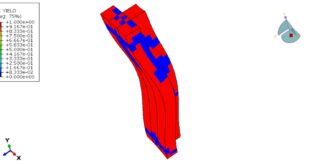

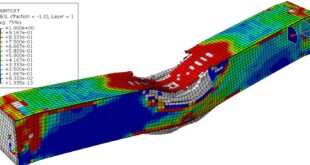

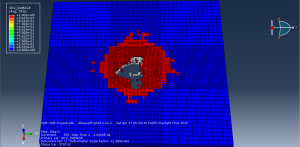

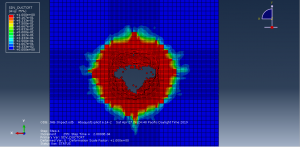

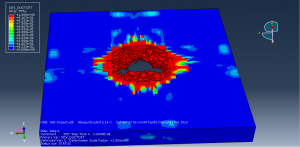

Dynamic explicit procedure is appropriate for this type of analysis. General contact by considering internal element erosion has defined as input file.The initial velocity 850m/s is assigned to the projectile. After the simulation all damage variable can be achievable . You can see some figures of the result at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials