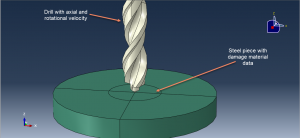

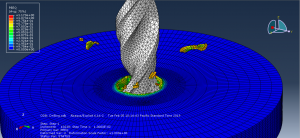

In this video Simulation steel drilling process in Abaqus has been investigated.Drilling process is one of the most required machining techniques that accounts for more than 40 % of the total material removal processes and especially has a high frequency of use in aerospace industries . It is significant to investigate the drilling mechanism. Though experimental method is a direct approach, it is time-consuming and inefficient to some extent. Numerical modeling method is widely considered as a valuable tool for predicting cutting forces, chip formation, tool wear, and distribution of important field variables such as strain, strain rate, temperatures, and stresses.In this study a 3D FE model for the drilling process has been developed using the FE package Abaqus/Explicit. The model is based on Lagrangian formulation.You can see a figure of the assembled part at below

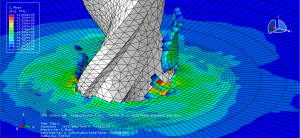

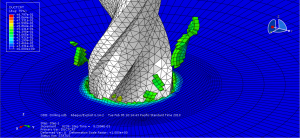

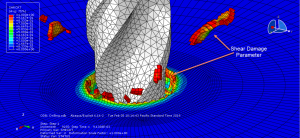

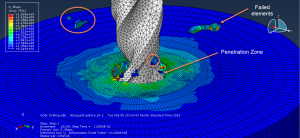

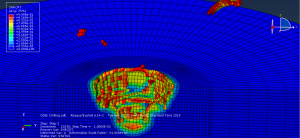

The steel part is modeled as a three dimensional part with elastic plastic material couple with ductile and shear damage .General contact algorithm as input file was generated to consider internal failing of element . During the simulation the drill penetrated into the steel par and create chips of it. You can see some figures of this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials