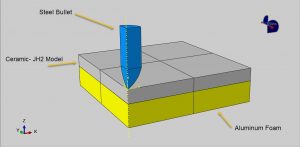

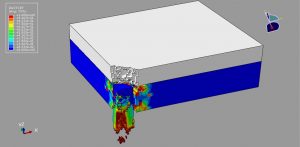

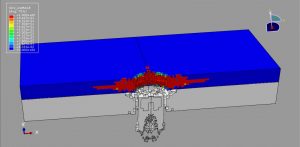

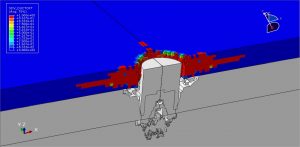

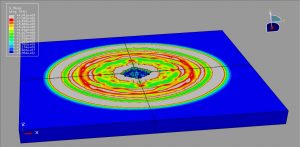

In this tutorial, the Simulation steel bullet impact to the armor panel(Ceramic- Aluminum Foam) in Abaqus has been investigated. The steel bullet is modeled as a three-dimensional solid part. The ceramic and aluminum foam are modeled as three-dimensional solid parts. Because of the symmetry conditions, one-quarter of the whole model is selected to reduce the time of the simulation. Damage investigation is the aim of this simulation. You can see a figure of the assembled parts below

To model steel bullet behavior, the elastic-plastic model with ductile and shear damage is used. Two main mechanisms can cause the fracture of a ductile metal: ductile fracture due to the nucleation, growth, and coalescence of voids; and shear fracture due to shear band localization. Based on phenomenological observations, these two mechanisms call for different forms of the criteria for the onset of damage. To model ceramic or silicon carbide material, the Johnson-Holmquist or JH2 model is selected. Ceramic materials are commonly used in armor protection applications. In recent years Johnson, Holmquist, and their coworkers have developed a series of constitutive relations to simulate the response of ceramic materials under large strain, high strain rate, and high-pressure impacting conditions. The JH-2 model assumes that the damage variable increases progressively with plastic deformation. To model metal foam behavior, the crushable foam hardening and ductile damage criterion is used

Dynamic explicit step with general contact capability is appropriate for this type of analysis. The perfect contact is assumed between the ceramic and aluminum foam plates. The symmetry boundary conditions are assigned to the symmetry zones. The initial velocity is applied to the steel bullet as a predefined field. The mesh should be fine to obtain correct results

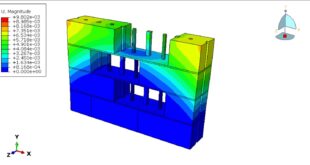

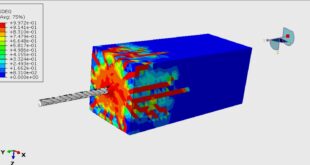

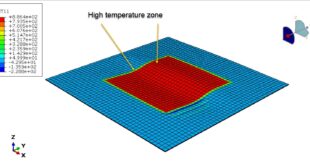

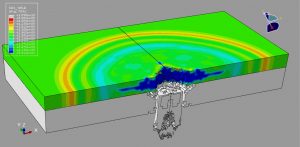

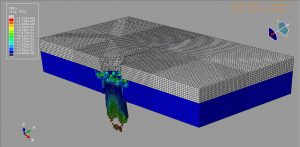

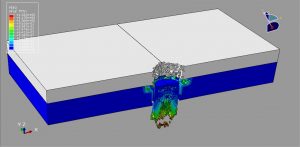

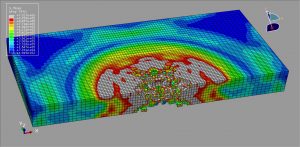

After the simulation, all results such as stress, strain, ductile and shear damage for the bullet, damage parameters for the ceramic, damage and failure for the metal foam, and… are avaialbe. You can see some figures for the results below

You can provide CAE, INP, and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment, send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials