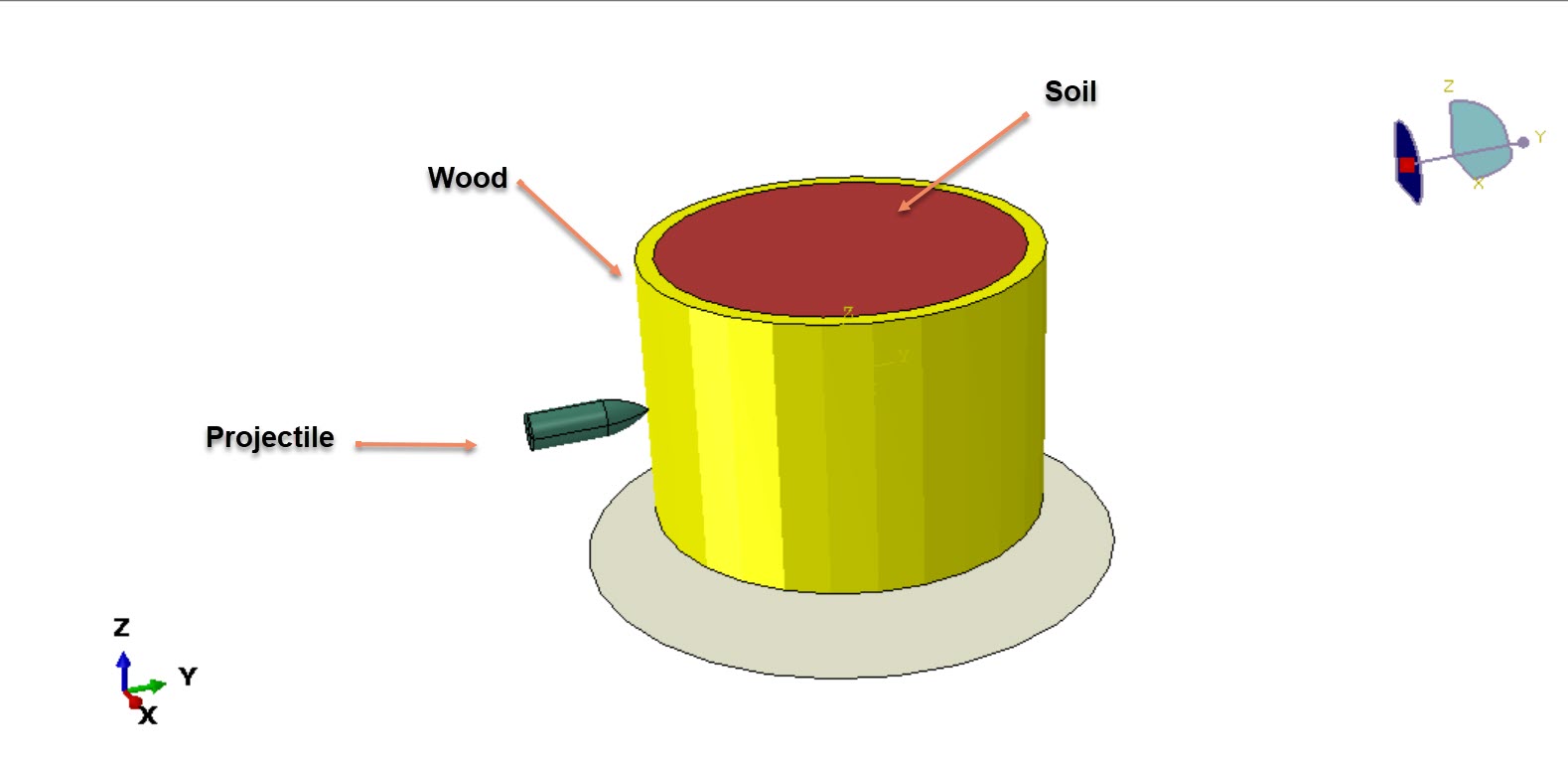

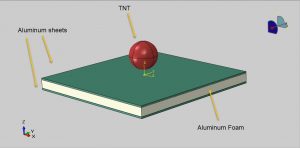

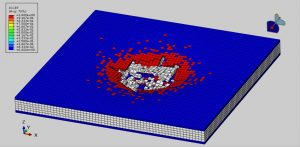

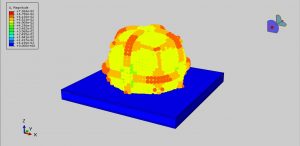

In this tutorial, the Simulation SPH explosion over the composite panel( Aluminum- Metal Foam) in Abaqus-Damage investigation – has been done. The explosive part, or the TNT is modeled as a three-dimensional solid part. The aluminum sheets are modeled as three-dimensional solid parts. The Aluminum Foam as a core is modeled as a three-dimensional solid part. You can see a figure of the assembled parts below.

Cellular materials, such as foams, are important lightweight materials to resist impact. Nowadays, more and more attention has been paid to these materials. Aluminum foam is produced through the foaming process after the additive is added into pure aluminum or aluminum alloy. It has both metal and bubble characteristics. It is of low density, high energy absorbability, high-temperature resistance, strong fireproof performance, and so on. Aluminum foam has extensive development prospects in industries of aerospace, transportation, architectural structure, and soon. The mechanical properties of the aluminum foam are the most fundamental and important properties

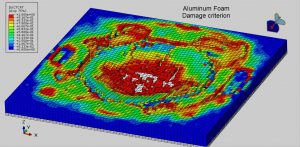

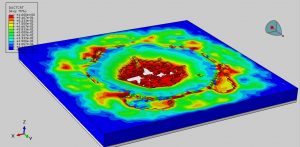

To model TNT behavior The Jones-Wilkins-Lee equation of state is selected. The Jones-Wilkins-Lee (or JWL) equation of state models the pressure generated by the release of chemical energy in an explosive. This model is implemented in a form referred to as a programmed burn, which means that the reaction and initiation of the explosive are not determined by shock in the material. Instead, the initiation time is determined by a geometric construction using the detonation wave speed and the distance of the material point from the detonation points. To model aluminum behavior under severe load, the Johnson-Cook hardening and damage criterion is used. The aluminum foam is modeled as an elastic material with Crushable foam hardening. To consider damage and failure of the metal foam, the ductile damage criterion is selected

The dynamic explicit step is appropriate for this type of analysis. The perfect contact is assumed between metal foam and aluminum sheets. The general contact capability with contact property is assumed among all parts. The fixed boundary condition is assigned to the composite panel. The mesh should be fine to obtain the correct results

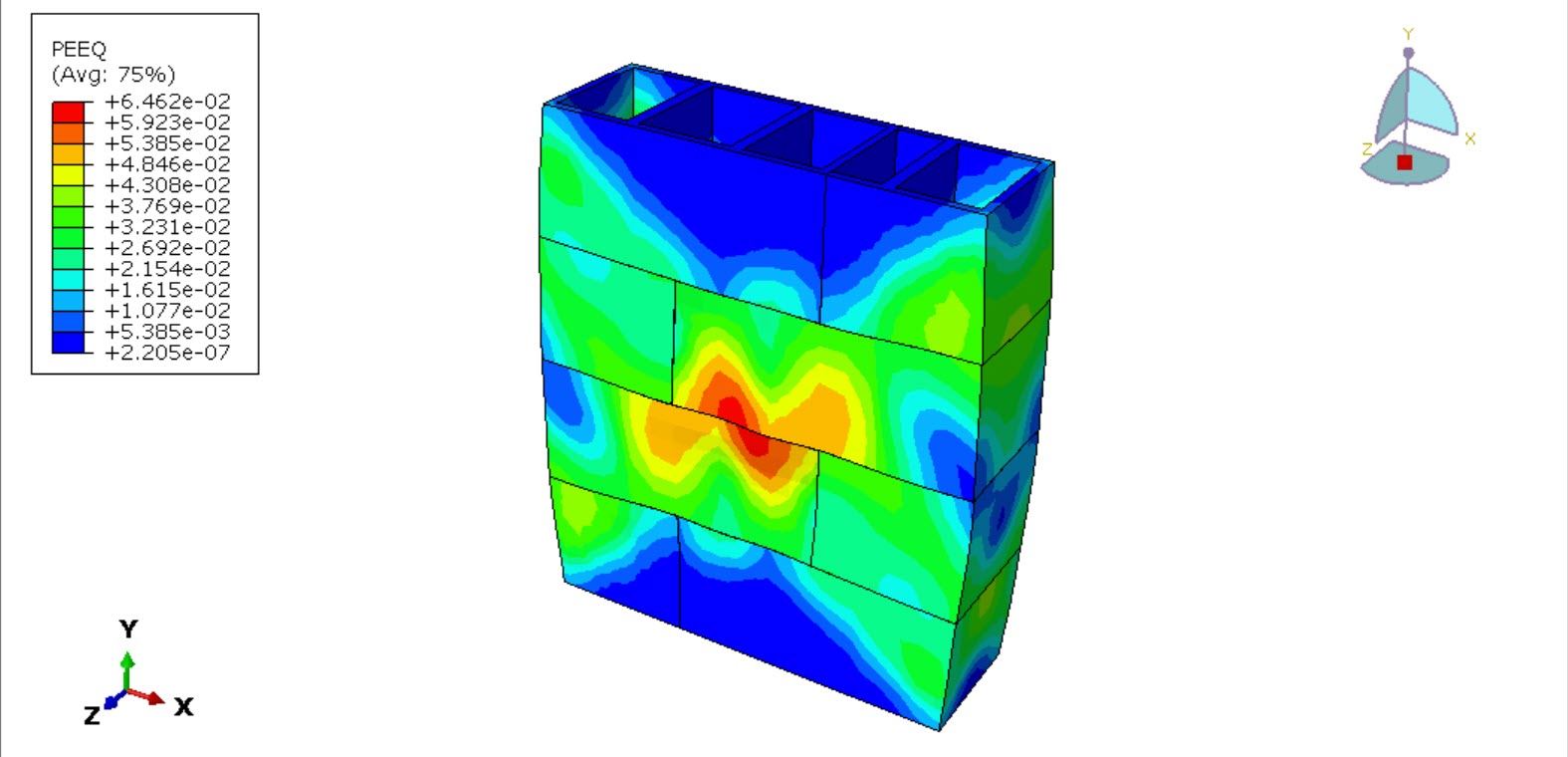

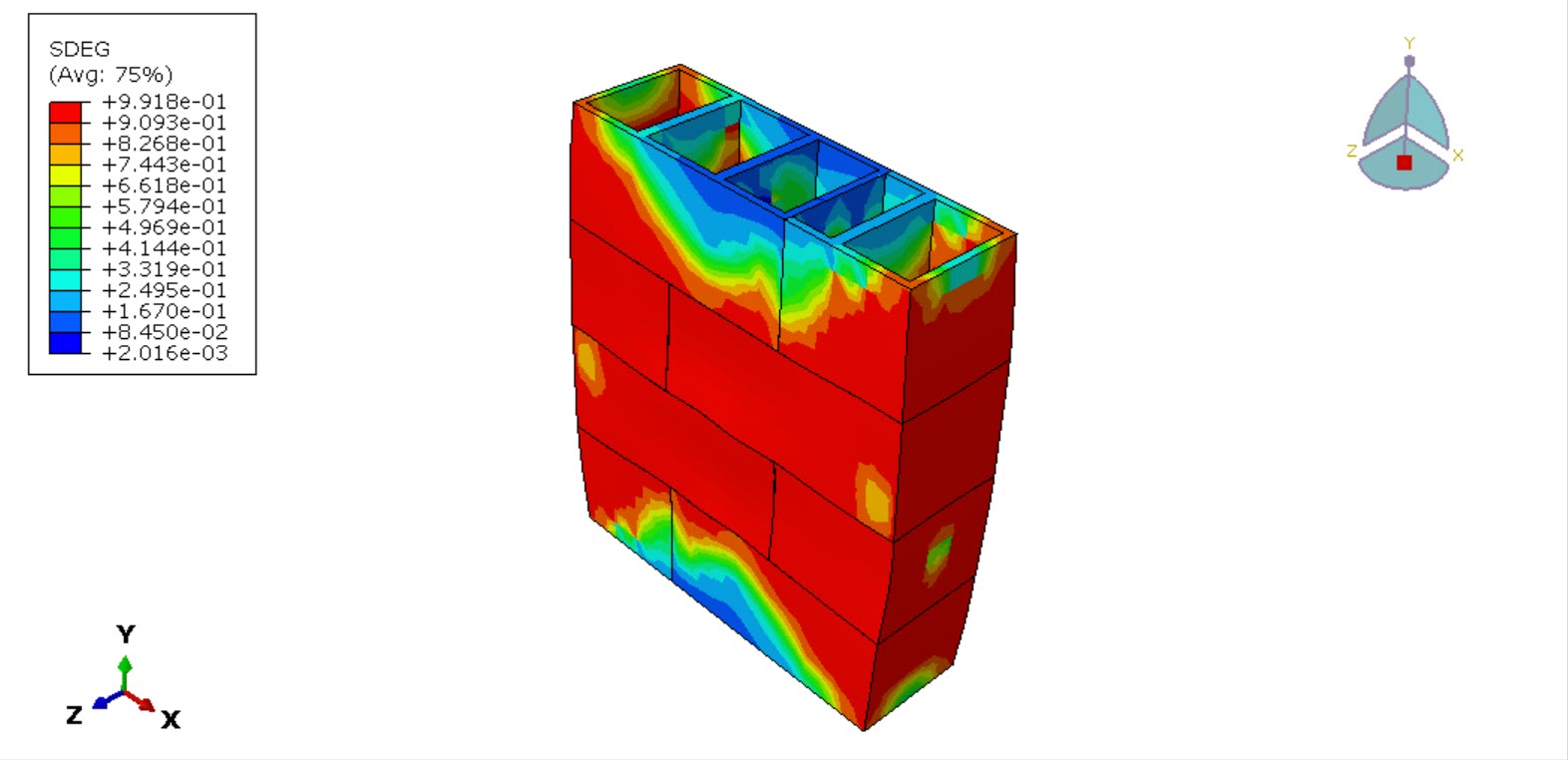

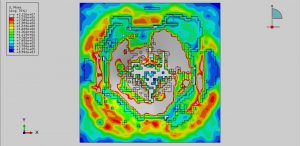

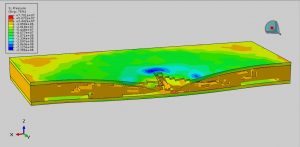

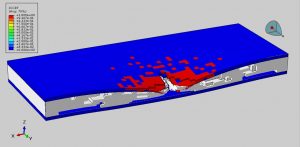

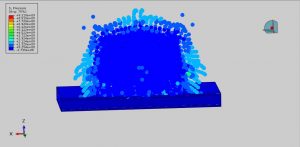

After the simulation, all results such as stress, strain, aluminum sheet damage, metal foam damage and failure, blast particle propagation, and… are available. You can see some figures for the results below

You can provide CAE, INP, and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment, send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials