Single point incremental forming is a flexible process which uses very simple tooling to make sheet metal prototypes and custom specific parts. In this, the sheet is clamped along its edges and a hemispherical headed tool is moved along required path so that it presses the sheet locally along the path. Better formability, simple tooling without any dedicated dies and low forming forces are some of the attractive features of this process.However, it suffers from some disadvantages such as long processing time, poor dimensional accuracy due to bending of the sheet near clamped edges. Tool diameter, step depth, feed rate, rotational speed of the spindle, sheet thickness, lubrication and tool path are some of the important process parameters which affect the process

mechanics in incremental forming.Tool path plays a vital role in the geometric accuracy of the part and homogeneous thickness distribution.Thus the proper tool path selection is very important for successful production of parts in incremental forming. Other ways of improving the accuracy of the part is by using contour tool, partial or full die below the sheet

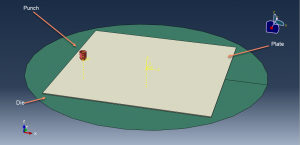

In this tutorial simulation single point incremental forming has been investigated. Plate is modeled as shell part and steel material has selected for it. You can see a figure of assembled parts at below

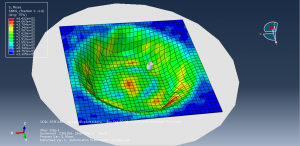

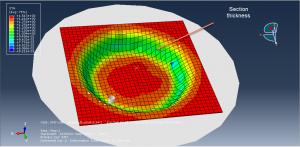

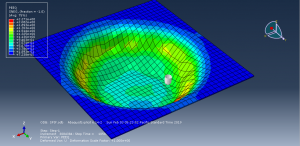

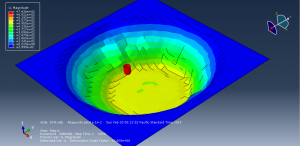

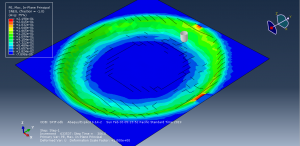

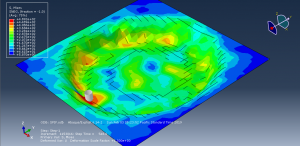

Dynamic explicit procedure is appropriate for this type of analysis and surface to surface contact is selected for contact algorithm. To define circular path amplitude has used along X,Y and Z direction. The paths are defined as excel file and imported it to the abaqus. After the analysis the stress, strain and section thickness can be investigated.You can see some figures of this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials