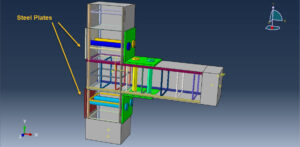

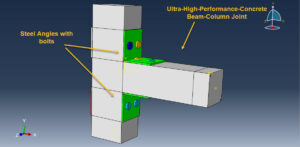

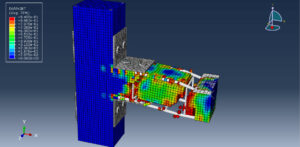

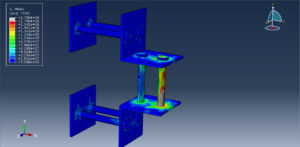

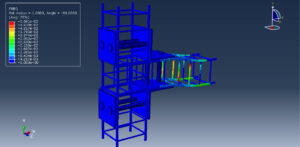

In this tutorial, the Simulation of the UHPC beam-column joint reinforced with steel angle and bolts in Abaqus has been investigated. The Ulta-High-Performance-Concrete beam-column joint is modeled as a three-dimensional solid part. The steel bar and strips are modeled as three-dimensional wire parts. The steel angle, plates, and bolts are modeled as three-dimensional solid parts. You can see figures of the assembled parts below

Reinforced concrete (RC) moment-resisting frame structures are the most common building type worldwide, including Bangladesh. A huge amount of concrete is produced each year worldwide, and the demand for concrete is increasing. The constituents of concrete are available in several variations, especially for coarse aggregates With the increasing demand for RC construction, the safety of such structures from seismic or dynamic load events is becoming more critical for the civil engineering community

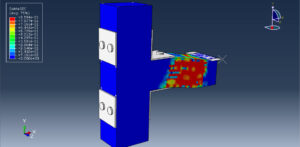

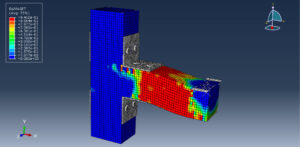

To model the UHPC joint under normal and axial loading, the Concrete Damage Plasticity is selected. The concrete damage plasticity material model represents a constitutive model that is based on a combination of the theory of plasticity and the theory of damage mechanics. This material model is often used in solving geotechnical problems due to its realistic description of the mechanical behavior of concrete material. To model steel behavior for all metal members, the elastic-plastic behavior with damage properties is considered

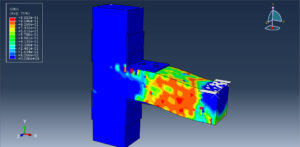

All interactions and constraints with proper mesh and boundaries are applied to the part. The mesh should be fine at the contact zones to obtain the better results

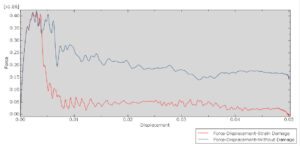

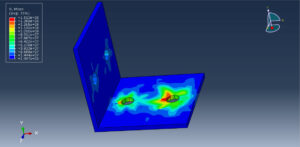

After the simulation, all results such as stress, strain, tension damage, compression damage, deformation, bearing capacity, and others are available. You can see some figures for the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials