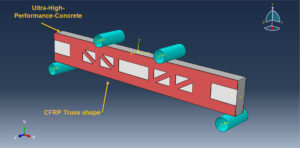

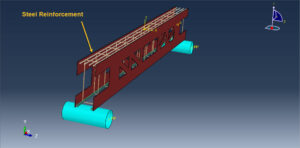

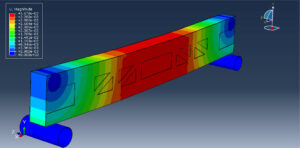

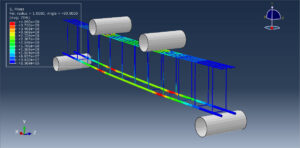

This tutorial investigates the Simulation of Shearing and bending Capacity of Concrete Beams Reinforced with Carbon Fiber Truss in Abaqus. The Ultra-High-Performance-Concrete beam is modeled as a three-dimensional solid part. The bar and strips are modeled as wire parts. The CFRP composite is modeled as a truss-shaped shell with eight layers. You can see figures of the assembled parts below

In recent years, small and medium-span reinforced concrete (RC) beams have suffered severe cracking at bearings and quarter spans, and shear diseases have been a severe phenomenon for bridges. Currently, many methods are used for the shear strengthening of RC beams, but some questions such as low reinforcement efficiency and poor durability still exist. Although externally bonded fiber-reinforced polymer (FRP) has been widely used to strengthen concrete bridges, the utilization efficiency of FRP still needs to be improved. A closed FRP truss combining externally U-type and side bonded FRP is proposed, which aims to enhance the utilization efficiency of FRP and the shear capacity of RC beams in this paper. The calculation model is established to predict the shear capacity of RC beams strengthened with FRP truss by theoretical study, model tests, and numerical simulations. FRP truss enhances the shear capacity of RC beams and the utilization efficiency of FRP. The finite element method is used to analyze the influence of the stirrup ratio on the FRP truss’s strengthening efficiency, proving that reinforcement effects gradually increase with the decrease of the stirrup ratio. Under ideal condition

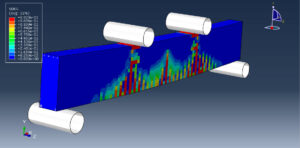

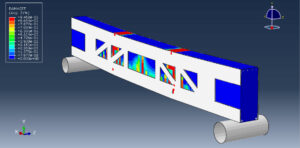

The concrete-damaged plasticity model is selected to model the UHPC beam in Abaqus. This continuum, plasticity-based damage model for concrete assumes that the main two failure mechanisms are tensile cracking and compressive crushing of the concrete material.

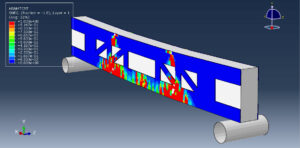

To model fiber damage in Abaqus, Hahsin’s damage criterion is used. Damage initiation refers to the onset of degradation at a material point. In Abaqus, the damage initiation criteria for fiber-reinforced composites are based on Hashin’s theory. These criteria consider four different damage initiation mechanisms: fiber tension, fiber compression, matrix tension, and matrix compression.

Both static and dynamic approaches are used in this tutorial. The proper interactions, constraints, load, and boundaries are assigned to all parts. The mesh should be fine to obtain the correct results

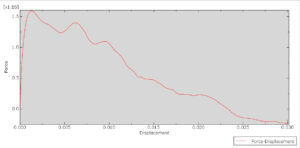

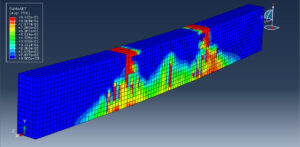

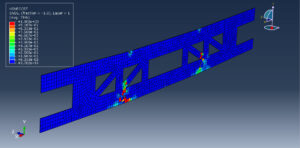

After the simulation, all results such as stress, strain, force-displacement diagram, tension and compression damage, fiber failure, and others are available. You can check some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials