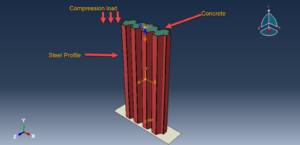

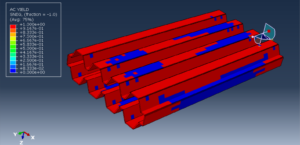

In this tutorial, the Simulation of composite panels made of profiled steel skins and concrete under axial compressive load in Abaqus has been studied. The steel profile is modeled as a three-dimensional shell part. The concrete core is modeled as a three-dimensional solid part. You can see a figure of the assembled parts below

Double-profiled steel composite wall (DPSCW) comprises vertically aligned profiled steel sheets and infill concrete. Profiled steel sheets

are widely used in composite constructions, especially those known as “fast-track constructions”. The steel sheets act as permanent formwork, obviating the need for expensive rebuilding of shutters. They also act as reinforcement to the wall and allow the concrete to be placed without the need for reinforcing bars. Therefore, the use of DPSCWs reduces the construction period and the need for laborers. Composite wall systems have also been applied in nuclear power plants and high-rise buildings in seismic regions as indicated in. Although there are a lot of efforts to study the behavior of steel-concrete composite panels, there are no standards available for this system to date. The lack of design guidelines has limited practical applications of this system

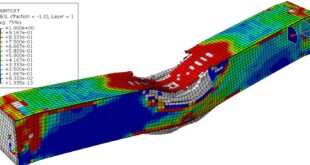

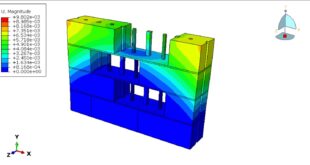

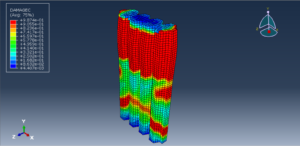

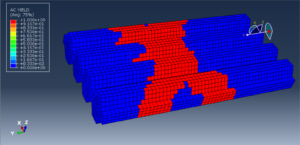

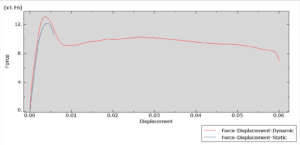

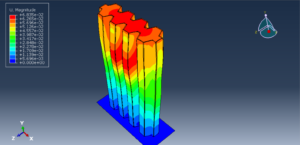

Finite element modeling (FEM) using ABAQUS standard software was carried out to understand the behavior of composite walls under axial compression loads, both static and dynamic approaches are implied, and compression has been considered between the two methods. All interactions, constraints, boundaries, and meshes are assigned to the parts

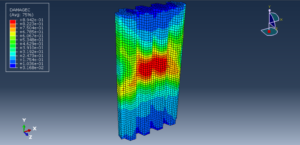

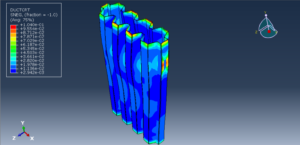

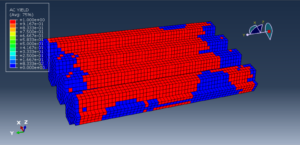

After the simulation all results such as stress, strain, tension and compression damage, steel profile damage, force displacement, and others are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials