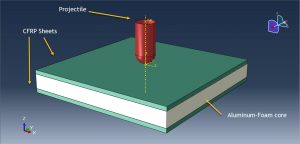

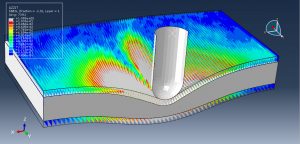

In this tutorial, the Simulation low velocity impact on the CFRP-AL Foam-CFRP panel in Abaqus has been investigated. The CFRP are modeled as three-dimensional solid parts with four different fiber direction. The Aluminum-Foam as a core part is modeled as a three-dimensional solid part. The projectile is modeled as the three-dimensional shell part. You can see a figure of the assembled parts below

Foam core sandwich structures comprising of two stiff and strong face sheets separated by a lightweight core show two distinct superiorities that are attractive for many applications. First, the separation of the face sheets by the core increases the moment of inertia of entire structures with little increase in weight, making them efficient structures for resisting bending and buckling loads. Second, they exhibit excellent energy absorption capability used for example in armor systems, which relies on the high porosity and compressibility of foam core. An essential factor for the implementation of foam core sandwich structures in structural components is their impact characteristics be-cause these structures are vulnerable to impact from foreign objects in service. Metal foams structures, due to its impact absorbing properties could be considered as passive safety systems in transportations which still have a great potential for development as a way to reduce deaths and injuries, which is also associated to the economic costs and social impacts associated with this problem. To model CFRP material, the elastic data with fail stress parameter and also Hashin’s damage criterion is selected. To model metal foam behavior under impact load, the Crushable Foam model with hardening is used. The dynamic explicit step is appropriate for this type of analysis. The surface to surface contact with friction as a contact property is selected between rigid projectile and the upper CFRP plate. The cohesive interaction by using stiffness parameters and also damage definition between CFRP sheets and foam core is used. The fixed boundary condition is assigned to two sides of the panel and initial velocity to rigid impactor. The mesh should be fine to achieve the correct results

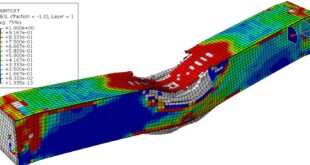

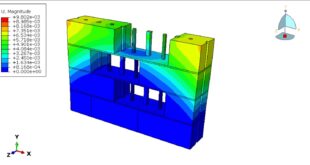

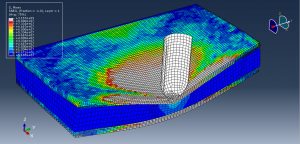

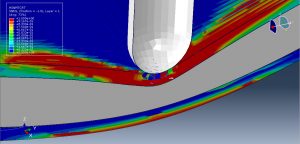

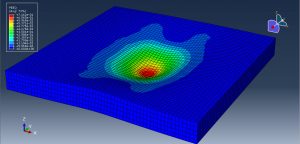

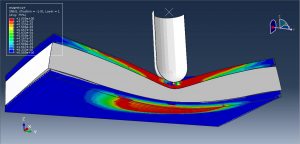

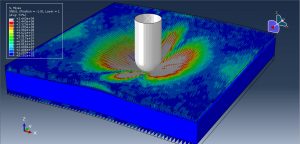

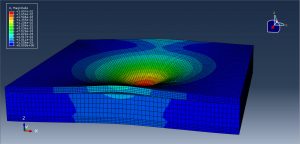

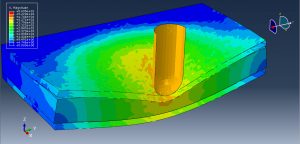

After the simulation, all results such stress, strain, damage and failure of the CFRP, displacement, and … are available. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment, send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials