Hydroforming is a metal fabricating and forming process which allows the shaping of metals such as steel, stainless steel, copper, aluminum, and brass. This process is a cost-effective and specialized type of die molding that utilizes highly pressurized fluid to form metal. Generally there are two classifications used to describe hydroforming, sheet hydroforming and tube hydroforming. Sheet hydroforming uses one die and a sheet of metal; the blank sheet is driven into the die by high pressure water on one side of the sheet forming the desired shape. Tube hydroforming is the expansion of metal tubes into a shape using two die halves, which contain the raw tube. Hydroforming is used to replace the older process of stamping two part halves and welding them together. It is also used to make parts both more efficiently by eliminating welding as well as creating complex shapes and contours. Parts created in this method have a number of manufacturing benefits including seamless bonding, increased part strength, and the ability to maintain high-quality surfaces for finishing purposes. When compared to traditional metal stamped and welded parts, hydroformed parts are lightweight, have a lower cost per unit, and are made with a higher stiffness to weight ratio. The processes can also be utilized in the single stage production of components; saving labor, tools, and materials.

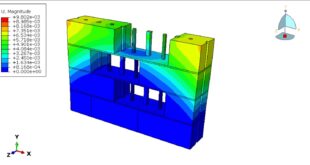

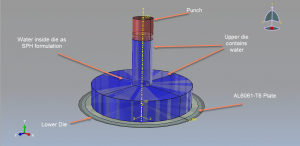

In this tutorial sheet hydroforming is investigated and you can see a figure about all assembled parts at below

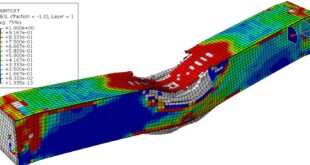

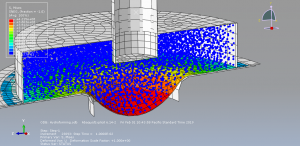

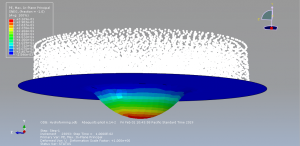

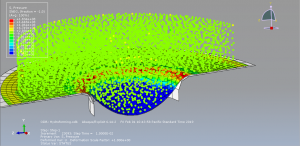

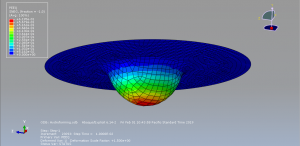

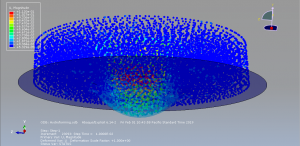

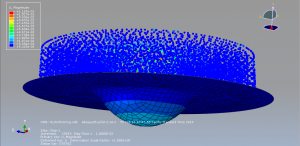

Aluminium material is used for the sheet and water is modeled as Us-Up equation of state. Dynamic explicit step with surface to surface contact has used . In this simulation Smooth Particle Hydrodynamic(SPH) to model water behavior is implied. During the simulation the punch moved into the water and water move to sheet and causes huge pressure over it and after a moment the forming of the sheet is obvious .You can see some figures of the result at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Two Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials