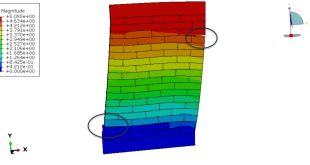

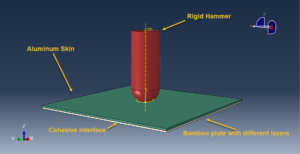

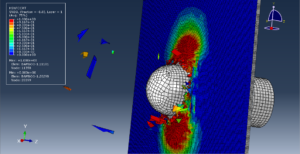

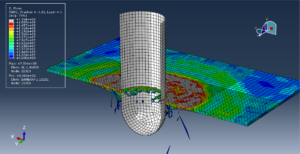

In this tutorial, the Simulation high-velocity impact on the Aluminum-Bamboo sandwich panel in Abaqus has been done. The aluminum plate is modeled as a three-dimensional solid part. The bamboo plate is modeled as a shell part with thirty two layers with different fiber angle. The projectile is modeled as a three-dimensional rigid shell part. You can see a figure of the assembled parts below

he configuration of a sandwich panel, which combines the advantages of joining two thin, stiff and strong skins to a thick and low-density core, results in superior crashing characteristics and impact resistance under out-of-plane loading when compared to single solid components.Sandwich structures are, however, susceptible to considerable damages during manufacture, transport, installation and service, which are caused by impacts from external objects, such as the collision of flying debris, dropped tools during maintenance, bird strikes and even rain hail

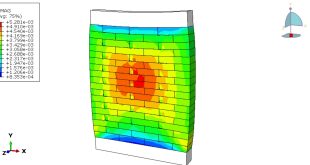

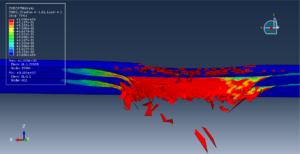

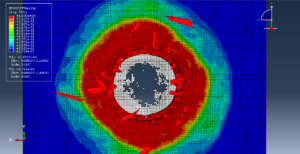

To model aluminum behavior under high-velocity impact, the Johnson-Cook plasticity model is selected. The Johnson-Cook plasticity model is a particular type of Mises plasticity model with analytical forms of the hardening law and rate dependence, and suitable for high-strain-rate deformation of many materials, including most metals. To consider the damage which happens during the analysis, the Jonson-Cook damage model is used also

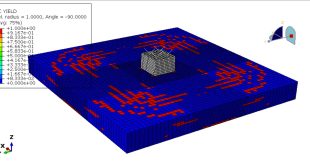

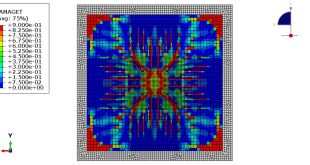

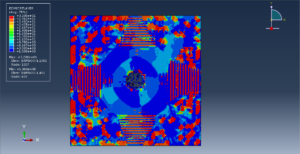

Damage initiation refers to the onset of degradation at a material point. In ABAQUS the damage initiation criteria for fiber reinforced composites are based on Hashin’s theory. These criteria consider four different damage initiation mechanisms: fiber tension, fiber compression, matrix tension, and matrix compression. The bamboo is modeled as 32 conventional layers with different orientation for the fiber

Dynamic explisit step is so appropriate for this type of analysis. A general contact algorithm (Explicit) accessible in the Abaqus/Explicit inter-action type is used in this analysis to define the contact between components. The cohesive contact method between the aluminum and bamboo is considered by using stiffness in three directions, damage, and fracture energy. The fix boundary condision is assigned to the panel and initial velocity to the projectile. the mesh should be fine to obtain the correct results

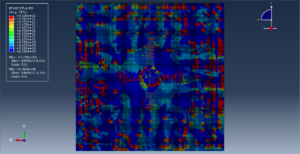

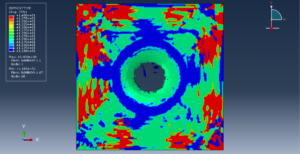

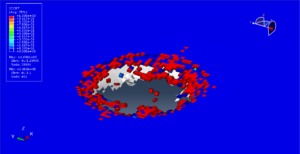

After the simulation, all results such as stress, strain, damage, failure, and… are available. you can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-six Euros. you can click on the bellow bottom to begin the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials