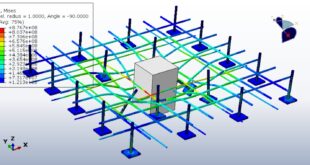

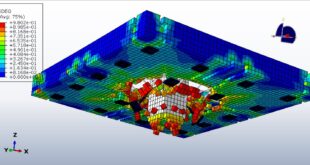

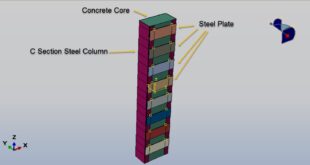

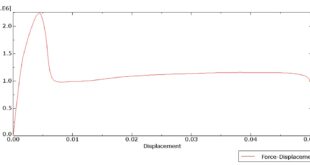

FSW problem is a multi-physics problem that includes excessive material deformation and heat flow .In the current work, a coupled Eulerian Lagrangian (CEL) model is developed using Abaqus environment to simulate the two phases of FSW process (plunging and welding).This file contain CAE and English video file step by step of FSW of two Aluminium plates.During the analysis tool move and rotate in the plates and create heat in them.Friction stir welding (FSW) is a solid state welding, which is recognized as a better process for joining similar and dissimilar metals and alloys with different physical, chemical, and mechanical properties.Friction stir welding is a complex process which involves interaction of thermal and mechanical phenomena: excessive material deformation around the pin tool accompanied by a large heat flow. Finite element modelling (FEM) of the FSW process leads to a better understanding of the effect of the process parameters on the welding process and the weld seam properties. Nowadays, FSW finite element models can be classified into three types: thermal, thermo-mechanical non-flow base, and thermo-mechanical flow-based models

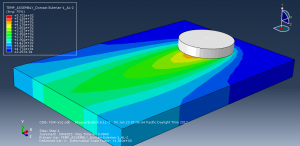

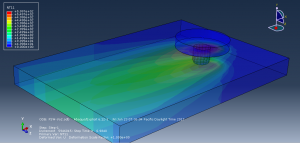

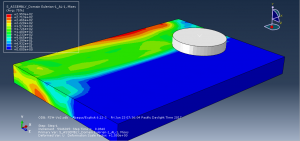

you can see some pictures of the results in the bellow

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials