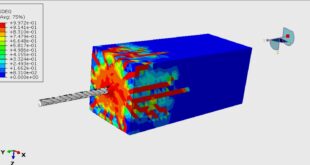

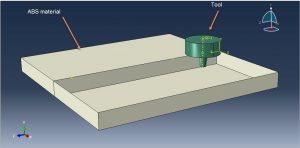

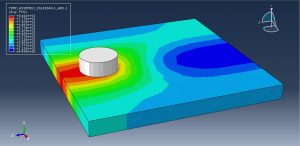

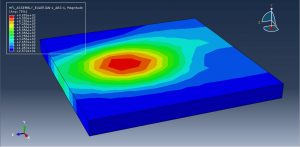

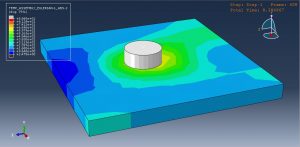

In this tutorial, the Simulation friction stir welding of acrylonitrile butadiene styrene polymer in Abaqus has been investigated. Polymer materials have seen its growth in leaps and bounds setting its foot in almost all manufacturing industries due to their excellent strength-to-weight ratio with enhanced toughness and low cost. Polymer joints are extensively used for automobile applications. One example is automotive tail-lights and indicators, in which a clear or tinted PC part is joined to an opaque body ABS. Polymers have different rheological properties especially in terms of melt viscosity, and thus, the flow behaviour is also different from metals which may be the main reason for the diversity of process parameters in FSW. Polymers which having higher melt temperature and viscosity require a higher tool rotational speed and a lower tool traverse speed to obtain adequate heat and finally, high joint efficiency. It is very challenging to join dissimilar polymers owing to the differences in their mechanical, chemical, thermal, metallurgical and physical properties, however; similar material exhibits good material compatibility that leading to more efficient joining. The ABS part is modeled as a three-dimensional Eulerian part. The tool is modeled as a three-dimensional solid part. You can see a figure of the assembled parts below

To model tool behavior, steel material with elastic-plastic data and thermal parameters is used. To model ABS material, elastic data and Johnson-Cook plasticity with thermal conductivity, specific heat, and…. is used. The dynamic temp explicit step is appropriate for this type of analysis. The friction coefficient with the heat generation parameter is used to define contact property. The rigid body constraint is implied for the tool to reduce the calculation volume during the FSW process. The fixed boundary condition is assigned to the sides of the Eulerian part and axial and rotation velocity to the tool. The uniform material assignment is used to model the Eulerian material location. The mesh should be fine to obtain good results

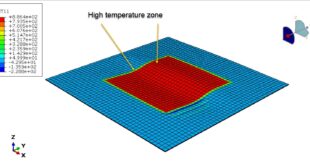

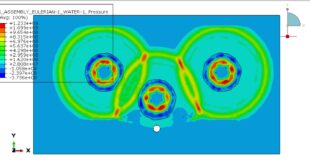

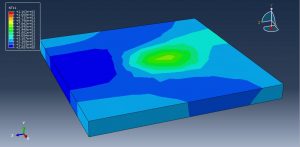

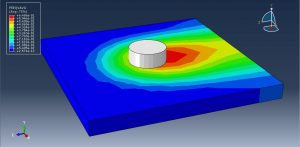

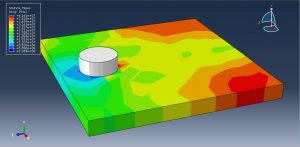

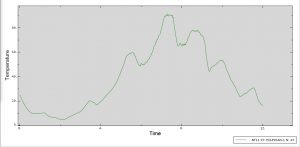

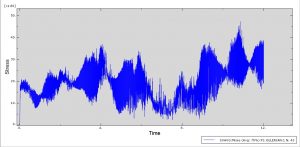

After the simulation all results such as temperature distribution, nodal temperature, stress, strain,…are achievable. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Nine Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials