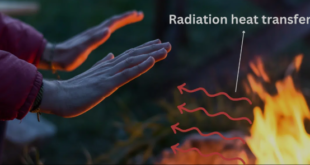

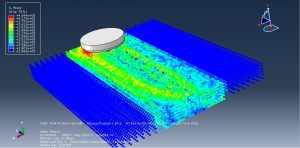

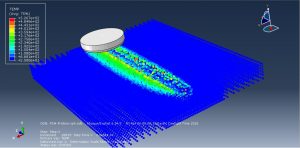

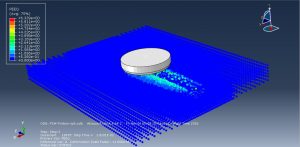

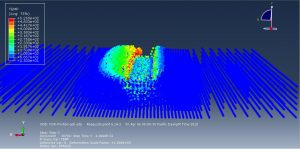

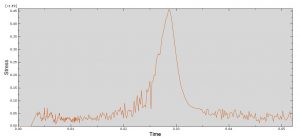

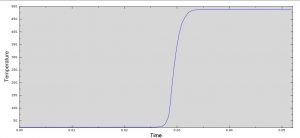

The friction stir welding (FSW) process is quickly becoming the joining method of choice for aluminum alloys. The solid-state process is able to form high-fidelity welds at excellent throughput rates. Because of the solid-state nature of the method, many types of defects are avoided that are associated with melting and solidification in conventional fusion welding processes. Nevertheless, depending on the process parameters, FSW joints can have volumetric defects that are detrimental to the ultimate strength of the joint. In this video Simulation Friction Stir Welding by using SPH method in Abaqus-Thermal analysis has been investigated. Abaqus doesn’t support SPH element couple with temperature degree ie PC3DT element, so by changing some points temperature has been applied to these type of element. This analysis contains three steps and during each steps stress and temperature changed. You can see some figures of this simulation at below.

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Seven Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials