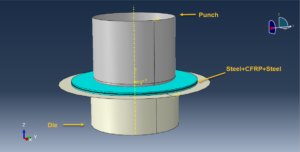

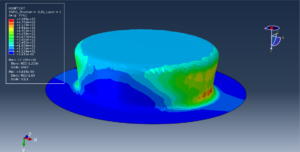

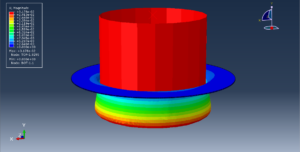

In this tutorial the Simulation forming process of steel-CFRP-steel composite plate in Abaqus has been done. The two steel plates are modeled as three-dimensional shell part. The CFRP core is modeled as a three-dimensional shell part with four layers. The die and punch are modeled as analytical rigid parts. You can see a figure of the assembled parts below

In the context of scarcer fossil raw materials and rising fuel prices, lightweight designs are increasingly entering the automotive industry. One of the key objectives in the development of future car generations is the reduction of fuel consumption and, concomitantly, the reduction of pollutant and CO2 emissions. A reduction in the vehicle weight leads to a greater ratio of payload to deadweight and, in addition, functions such as acceleration and driving dynamics are better met. A lower mass results in lower acceleration, ascent, and rolling resistances. A common approach is the substitution of high-density materials such as steel by lighter, low density materials with a high strength, such as CFRP. Significant weight advantages can be realized by using composite materials. However, the high material costs and the necessity of employing manual manufacturing processes limit the use of just composites to the high-priced car segment. One promising approach is structural components in a multi material design, such as hybrid parts made of high-strength steel with local CFRP reinforcements. Such hybrid components have cost advantages compared with exclusively CFRP components and can be reinforced in a load-adapted manner.

An alternative, promising approach for the economic, automated mass production of lightweight structures with a high stiffness-to-weight ratio is the combination of high-strength steel alloys and CFRP prepregs in special hybrid material – fiber-metal laminate (FML), which can be further processed by forming processes such as deep drawing. FML consists of metal sheet top layers with a CFRP core. The CFRP patches are chambered within the sheet metal layers and are not in direct contact with the tool surfaces. Compared to the forming of just composites, the forming process can be simplified and the process chain gets shorter, which is significantly more economic. Fiber metal laminates also have the particular advantage that the mechanical properties of the components produced can be adjusted by the number of CFRP layers and the fiber orientation of the individual patches within the layers

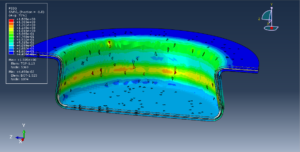

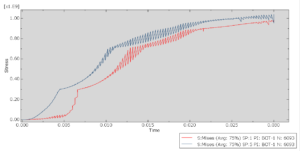

The elastic-plastic material model is selected for the steel parts, the lamina elasticity with Hashin’s damage criterion is selected to model CFRP material. The dynamic explicit step with mass scale technique is used to consider the dynamic process of forming. The surace to surface contact with property is selected for the punch, die and steel plates. The perfect contact is amoung the plates. The proper boundary conditions are assigned to the die and punch. The mesh should be fine to obtain the correct results

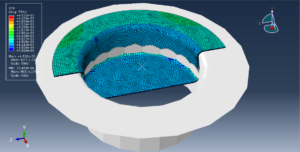

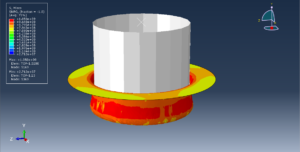

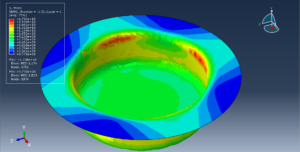

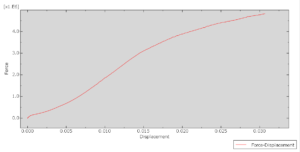

After the simulation, all results such as stress, strain, displacement, damage,… are available. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-six Euros. you can click on the bellow bottom to begin the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials