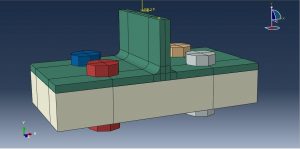

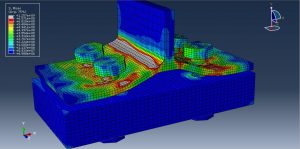

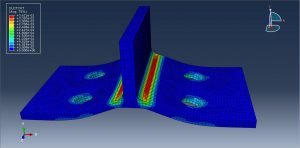

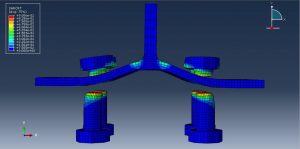

In this tutorial, the Simulation dynamic bolt failure (bolt and steel plates joint) in Abaqus has been studied. The upper and bottom steel plates are modeled as three-dimensional solid parts. The bolts are modeled as three-dimensional solid parts. You can see a figure of the assembled parts below.

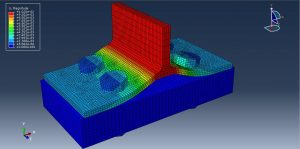

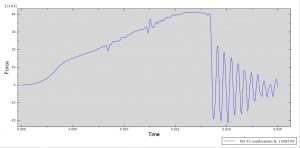

Two main mechanisms can cause the fracture of a ductile metal: ductile fracture due to the nucleation, growth, and coalescence of voids; and shear fracture due to shear band localization. Based on phenomenological observations, these two mechanisms call for different forms of the criteria for the onset of damage. The ductile criterion is a phenomenological model for predicting the onset of damage due to nucleation, growth, and coalescence of voids. The shear criterion is a phenomenological model for predicting the onset of damage due to shear band localization. To observe the failure and damage those criteria were used. The dynamic explicit step with a mass-scale technique is used to model the dynamic failure of the bolts. The surface to surface interaction with interaction property like friction is considered. The fixed boundary condition is assigned to the two sides of the bedplate and displacement with a smooth amplitude to apply smooth load to the upper steel plate. The mesh should be fine to achieve good results. These parts need many partitions to use a good mesh

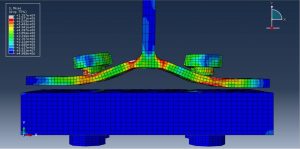

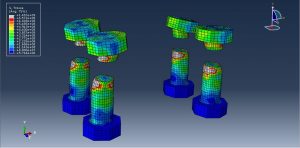

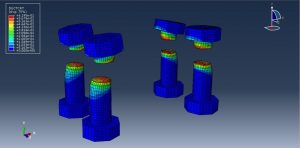

After the simulation, all results such as stress, strain, damage, failure, and displacement are obtainable. You can some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials