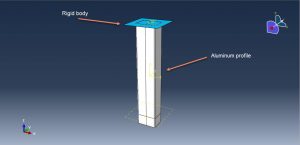

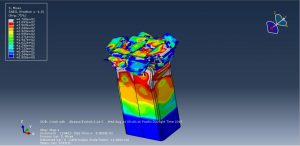

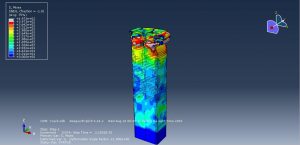

In this tutorial, Simulation Crashworthiness behavior of aluminum profiles with holes considering damage criteria and damage evolution has been studied. Recently, the use of thin-walled structures in automobiles to increase the safety and integrity of passengers during car collisions, have gained importance by automotive manufacturers and designers. An important characteristic of these structures is the capacity to absorb kinetic energy by plastic deformation. For this purpose, profiles made of different metals like magnesium, steel, and aluminum alloys have been analyzed. In the automobile industry, aluminum alloys show some design advantages with respect to other materials in terms of corrosion resistance and structural lightness. Compared with steel profiles, structures made of aluminum can reduce up to ۲۸% of total the weight of a vehicle. This condition has a clear advantage on the reduction of fuel consumption, minimizing also the emission of harmful contaminant agents to the environment. The aluminum profile is modeled as a three-dimensional shell part that you can see the assembled parts at below

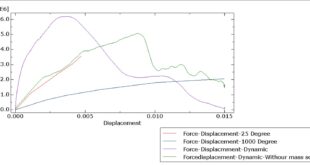

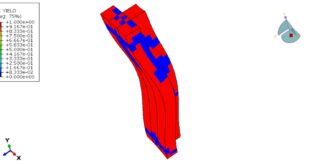

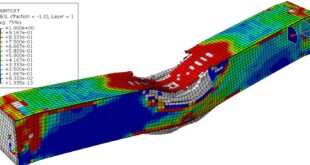

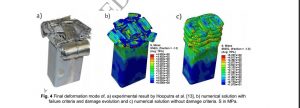

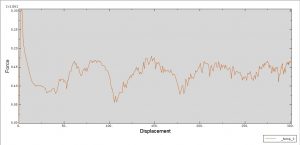

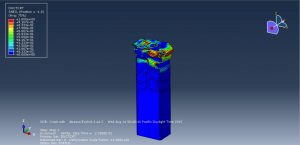

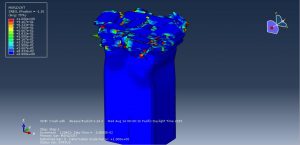

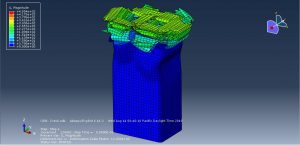

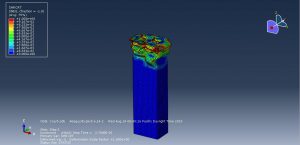

The sheer damage criterion with evolution, the ductile damage criterion with evolution, and the MSFLD damage criterion with evolution to predict the exact behavior of the aluminum part under impact has been used. The dynamic explicit procedure is used to model the dynamic behavior of the crash phenomenon. The general contact interaction with the contact property is assigned to the contact domain. The fixed boundary conditions are assigned to the bottom surfaces of the aluminum profile and displacement to the top rigid plate. The mesh should be fine to get the correct result of compaction. After the simulation, all damage criteria, stress, strain, and other results can be available. You can see some figures for the result below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Five Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials