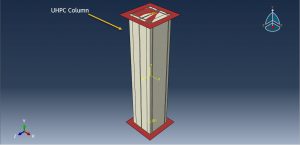

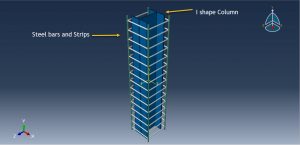

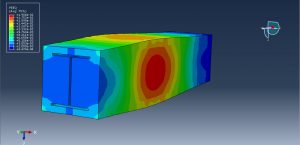

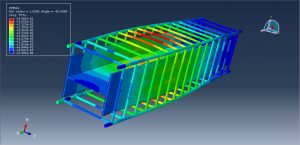

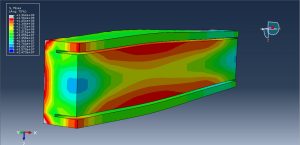

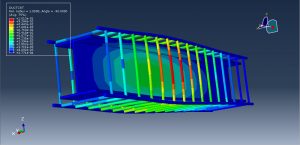

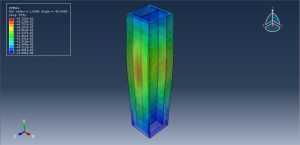

In this tutorial, the Simulation compression test of an encased steel-UHPC composite column using Abaqus has been done. The UHPC column is modeled as a three-dimensional solid part. The I shape steel column is modeled as a three-dimensional solid part. The steel bars and strips are modeled as three-dimensional wire parts. You can see a figures of the assembled parts below

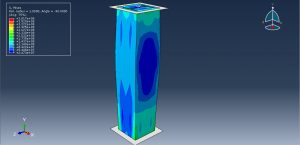

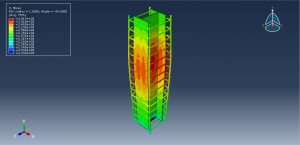

Composite columns are constructed with structural steel inside concrete or concrete inside structural steel. These are structural elements using a combination of steel shapes, shapes, pipes or tubes with or without reinforcement and concrete to bear axial compressive loads or a combination of axial and bending moments on its own. All concrete and steel sections in the composite column withstand external loads by interacting with contact and friction. The composite column can bring economic benefits and handle large amounts of load with a lesser cross-section compared to con-trol columns. The advantage is resistance to fire and corrosion among standard steel columns. Structural steel has characteristics like high strength, high ductility and high stiffness which is best advantage for load carrying capacity. Although concrete is the most universally used material in building there are still some limitations to its use, such as low tensile strength and brittleness. Ultra-High Performance Concrete (UHPC), a cutting-edge concrete, may be able to overcome these concerns. The Concrete Damaged Plasticity is selected to define UHPC material. The elastic-plastic material model couple with ductile damage criterion is used to define steel material behavior. The general static step with some changes in the convergence model is used. The general contact algorithm with friction behavior is considered for all contacts in the contact zones. The embedded region constraint is assigned to the bars and strips inside the UHPC host. The perfect or ideal contact is used to define the interaction between UHPC and steel column. The fixed boundary condition is assigned to the bottom of the column and load is applied to the top rigid body. The mesh be fine to obtain correct results.

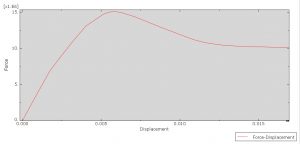

After the simulation all results such as stress, strain, damage, force-displacement diagram, and … are available. You can see figures of the assembled parts below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Eight Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials