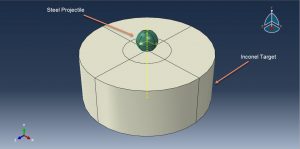

In this tutorial, the Simulation cold spray process of steel particle on the Inconel surface by using the ALE method in Abaqus has been studied. The steel particle is modeled as a three-dimensional solid part. The Nickel-Chromium(Inconel) part is modeled as a three dimensional solid part. You can see a figure of the assembled parts below

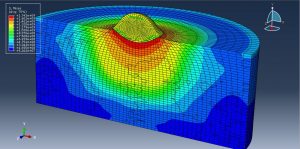

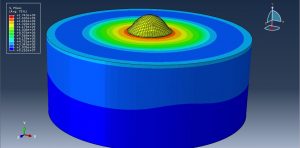

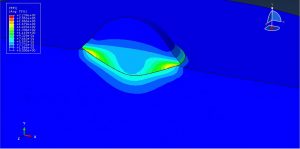

A numerical model for the impact of the steel ball on the surface of Inconel targets was developed by the finite element method using the ALE method. The plastic deformation of the target specimen was simulated using the J–C plasticity model. In addition, the steel ball was modeled as elastic and Johnson-Cook plasticity. The thermal properties for both parts because of the temperature change during the simulation are used. Dynamic, Temp-Disp, Explicit solving procedure is used to model the relation between stress and temperature during the simulation. The surface to surface contact with contact property like friction is used. The movement of the target was constrained in three directions. The initial velocity is assigned to the steel projectile. arbitrary Lagrangian-Eulerian (ALE) is considered to refine the mesh during the simulation. The mesh should be fine at the contact zone because of the deformation and high-temperature rate there

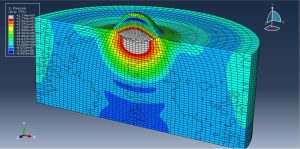

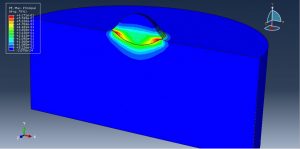

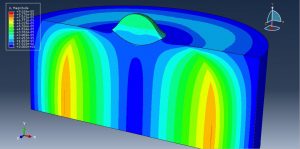

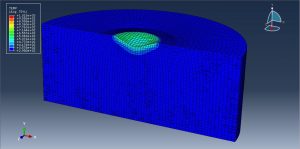

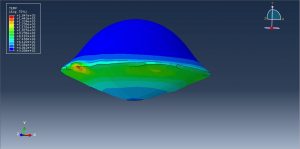

After the simulation, all results such as stress, strain, plastic strain, temperature, and…are obtainable. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials