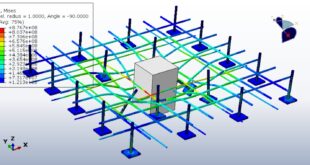

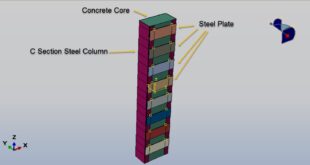

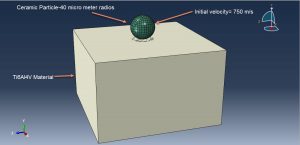

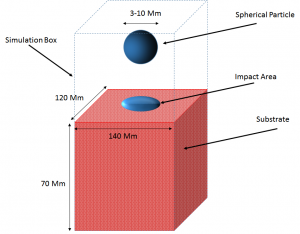

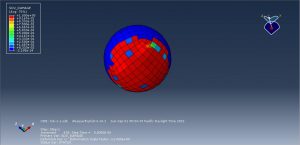

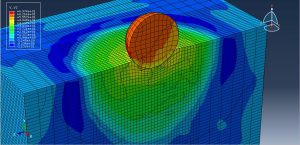

In this tutorial, the Simulation cold spray process of ceramic particles’ impact on the titanium target in Abaqus has been studied. The ceramic impactor is modeled as a three-dimensional sphere part with a forty-micrometer radius. and this is the minimum size of the sphere radius in Abaqus. The titanium target is modeled as a three-dimensional part. In this tutorial, the beggier part size is used than the real size. You can see figures of the assembled parts at below

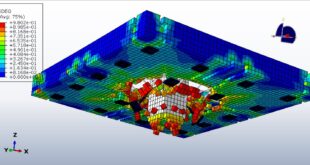

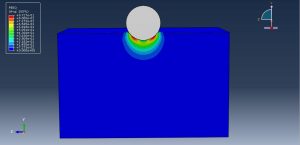

The titanium material is modeled as an elastic-plastic material with Johnson-Cook behavior and Johnson-Cook damage to predict the damaged zone. The Johnson-Cook material model can predict the deformation under the rapid load perfectly. The ceramic material can be modeled as some material models which Abaqus recommended. In this simulation, the Johnson-Holmquist ceramic material model is used to consider the silicon carbide behavior in the high-velocity impact. The dynamic explicit step is used with the surface to surface contact algorithm with contact property. The fixed boundary for the target and initial velocity for the ceramic as a projectile are assigned. The mesh should be fine at the contact zone but because of the dimension, the size of the mesh can not be used to small and that is a restriction in micrometer modeling

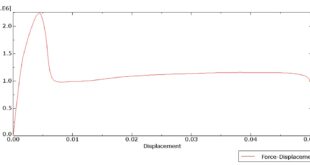

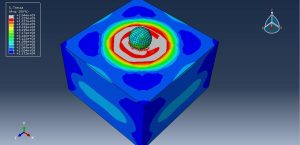

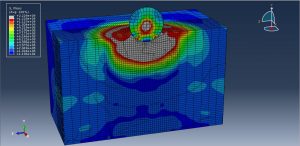

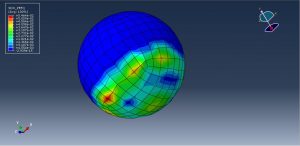

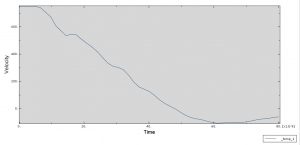

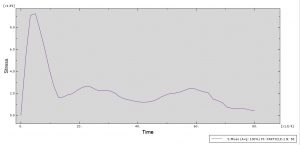

After the simulation all results such as stress, strain, plastic strain, and damage are achievable. You can see some figures for the result below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Nine Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials