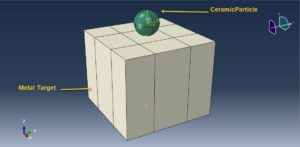

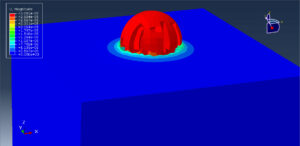

Simulation cold spray process of a ceramic particle on the steel material in Abaqus has been done in this tutorial. The ceramic particle is modeled as a three-dimensional solid part. The steel target is modeled a solid part. The dimension of all parts are micrometer. You can see a figure of the assembled parts below

Cold spray is a materials deposition process whereby combinations of metallic and non-metallic particles are consolidated to form a coating or freestanding structure by means of ballistic impingement upon a suitable substrate.he particles utilized are in the form of commercially available powders, typically ranging in size from 5 to 100 μm, which are accelerated from 300 to 1500 m/s by injection into a high-velocity stream of gas. The high-velocity gas stream is generated via the expansion of a pressurized, preheated, gas through a converging–diverging de Laval rocket nozzle. The pressurized gas is expanded to supersonic velocity, with an accompanying decrease in pressure and temperaturehe particles, initially carried by a separate gas stream, are injected into the nozzle either prior to the throat of the nozzle or downstream of the throat. The particles are subsequently accelerated by the main nozzle gas flow and are impacted onto a substrate after exiting the nozzle

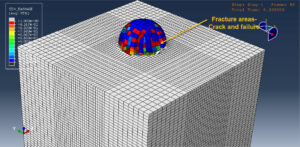

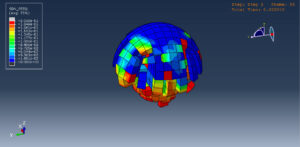

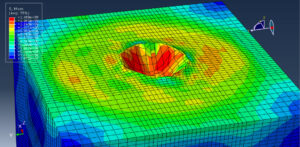

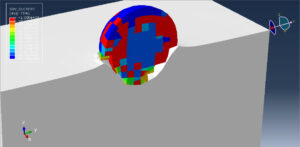

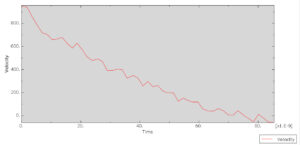

To model steel behavior under high strain rate, the Johnson-Cook hardening and damage is selected. To model brittle behavior of the ceramic particle, the Johnson-Holmquist material model is used. The dynamic explicit step and surface to surface contact is appropriate for this example. The proper boundary, initial velocity, and mesh are selected for all parts

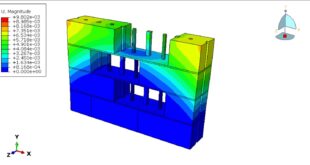

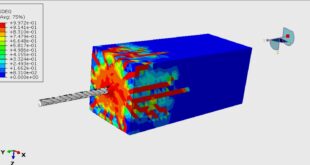

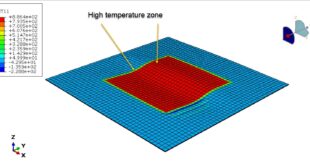

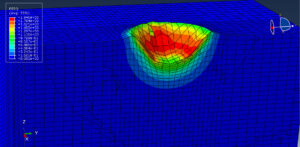

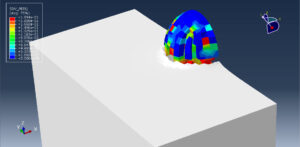

After the simulation, all results such as stress, strain, failure, deformation, ceramic damage, cohesion, and others are available. You can see some figures for the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials