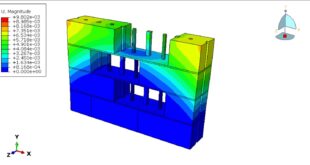

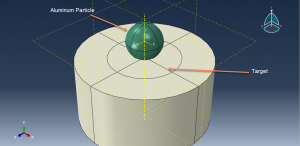

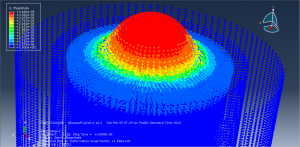

In this tutorial Simulation cold spray process by using SPH method in Abaqus has been investigated. In Cold Spray, powder particles (typically 10 to 40 µm) are accelerated to very high velocities (200 to 1200 m.s-1) by a supersonic compressed gas jet at temperatures below their melting point. Upon impact with the substrate, the particles experience extreme and rapid plastic deformation which disrupts the thin surface oxide films that are present on all metals and alloys. This allows intimate conformal contact between the exposed metal surfaces under high local pressure, permitting bonding to occur and thick layers of deposited material to be built up rapidly. The deposition efficiency is very high, above 90% in some cases.Whilst thermal spray is widely used in many applications, it uses thermal energy to melt or soften the feedstock. This can cause thermal degradation and partial oxidation of the coating material which may be undesirable. For metallic materials that are very prone to oxidation, thermal spray needs to be conducted under protected atmosphere or a vacuum, introducing extra cost.The heat input of thermal spray processes introduces residual stress into the coatings, which can limit the thicknesses that can be attained. Furthermore, the thermal balance has to be carefully managed through part cooling and gun manipulation to avoid excessive internal stresses and, in the case of thermally sensitive substrates, potential substrate degradation.With cold spray however, materials can be deposited without high thermal loads, producing coatings with low porosity and oxygen content.You can see a figure of assembled parts at below

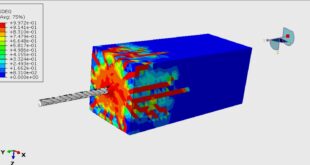

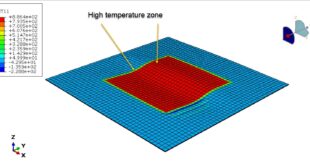

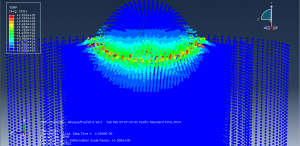

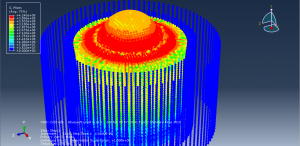

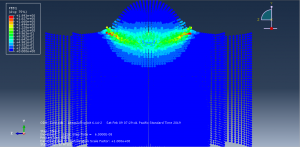

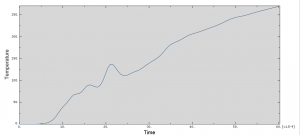

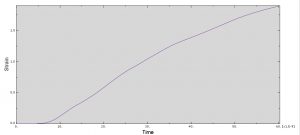

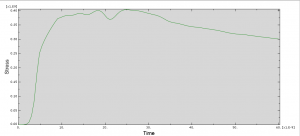

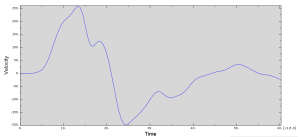

SPH formulation with dynamic explicit procedure has used and were made some changes in step to consider thermal variable at outputs because the SPH element dose not consider temperature degree. High initial velocity is applied to the particle and during the simulation a large plastic stain happen in the parts and the temperature is far from the melting temperature and it is a proper result for the cold spray process. You can see some figures of this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials