With the growing threat and risk of attacks and explosions in densely populated urban environments, the need for advanced security glass in windows, doors, police protective galss shield, and glass partitions is also increasing. In a powerful explosion, conventional glass panes will splinter even at a great distance from the explosion, often with serious splinter injuries as a consequence. In properties located in the immediate vicinity of the explosion even splinter-free panes will be forced in, despite being made from toughened or laminated glass

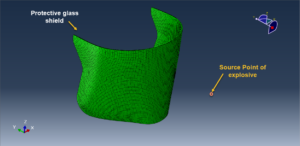

In this tutorial, the Simulation close explosion test of a glass shield in Abaqus has been investigated. The shield is modeled as three-dimensional soild part, and the part is imported to the Abaqus because of its curve. You can see a figure of the shield and the the TNT location in the below figure

To model glass shield behavior under severe load, the Johnson-Holmquist model is selected. The Johnson-Holmquist material model (JH-2), with damage, is useful when modeling brittle materials, such as ceramics,and glass subjected to large pressures, shear strain and high strain rates. The model attempts to include the phenomena encountered when brittle materials are subjected to load and damage, and is one of the most widely used models when dealing with ballistic impact on ceramics or glass. The model simulates the increase in strength shown by ceramics subjected to hydrostatic pressure as well as the reduction in strength shown by damaged ceramics or glasses. This is done by basing the model on two sets of curves that plot the yield stress against the pressure. The first set of curves accounts for the intact material, while the second one accounts for the failed material

The dynamic explicit step is appropraite for this type of analysis. The CONWEP method is considered as the explosion method, in this way we need to define the location and the mass of the explosive charge. The proper boundary condition is assigend to the part. The mesh should be fine to obtain the accure and exact results

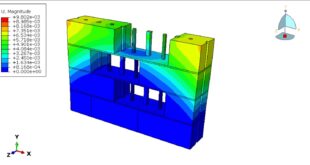

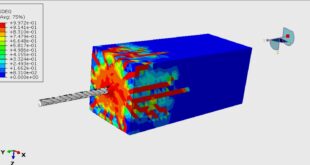

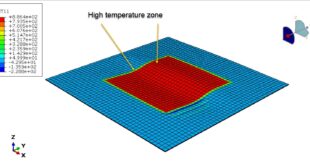

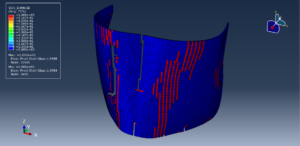

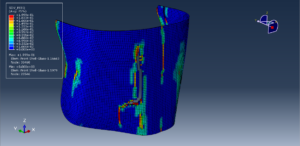

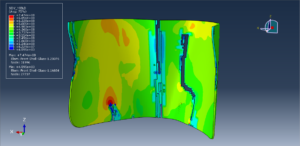

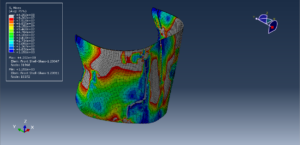

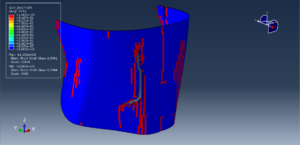

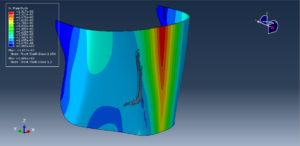

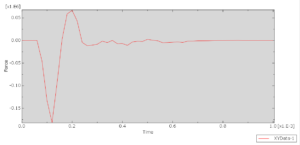

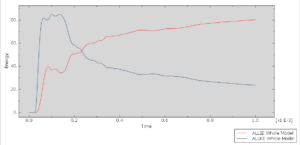

After the simulation, you can see all resutls such as stress, strain, damage, failure, crack pattern,…You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials