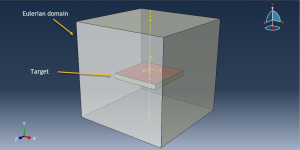

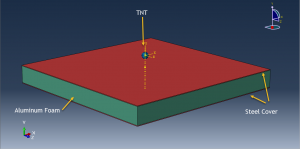

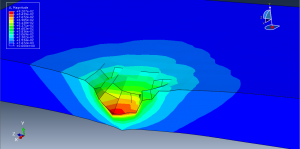

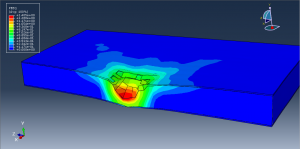

In this tutorial, the Simulation CEL explosion over composite panel(Steel and Aluminum Foam) in Abaqus has been studied. The steel sheets and aluminum foam core are modeled as three-dimensional solid parts. The TNT part is modeled as a three-dimensional solid part. The domain is modeled as a three-dimensional Eulerian part. You can see figures of the assembled parts below

The lightweight sandwich structures provides an attractive alternative solution to the problem. Cellular foam core sandwich structures, as a key member in the family of lightweight structures, are of current research and interests due to their high strength-to-weight ratio, stiffness-to-weight ratio and superior energy absorption capability. Especially, the microstructure of foam cores endows them with the ability to undergo large plastic deformation under a relatively long low plateau stress, and thus they could continue to behave excellent blast resistance before collapsing into a more stable state or fracture. The elastic-plastic material data with ductile and shear damage are used to model steel faces behavior under blast load. The aluminum foam is modeled as elastic material with crushable foam model. The TNT is modeled as a equation of state JWL to consider mechanical pressure comes from the chemical energy which released from the explosion. The dynamic explicit step is appropriate for this type of analysis. The ALE method is considered to regenerate the mesh during the simulation to avoid distortion. The general contact algorithm with contact property is selected. The proper boundary condition is assigned to the parts. The volume faction method is used to specify the amount and location of the TNT material in the Eulerian domain. The mesh should be fine to obtain good results

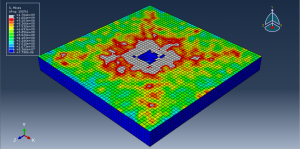

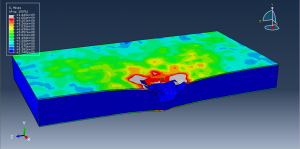

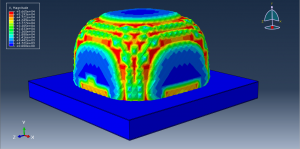

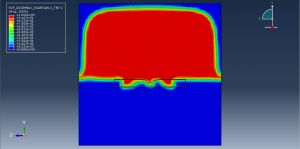

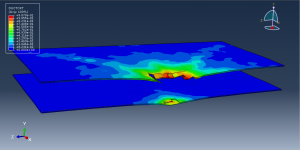

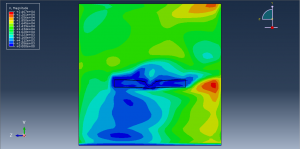

After the simulation, all results such as stress, strain, damage, failure, aluminum foam compaction, and … are available. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Nine Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials