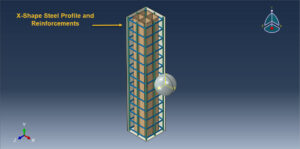

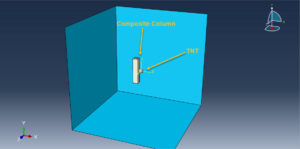

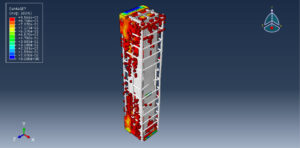

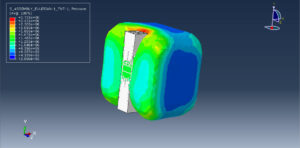

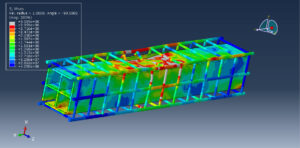

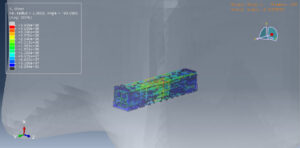

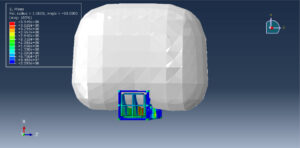

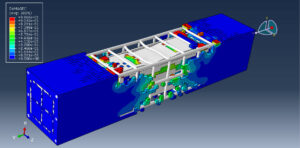

This tutorial simulated a CEL explosion over a composite RC column with an X-shaped steel core in Abaqus. The concrete and steel X-shaped columns are modeled as three-dimensional solid parts. The steel reinforcements are modeled as wire parts, and the domain that contains explosive charge is modeled as an Eulerian part. You can see figures of the assembled parts below

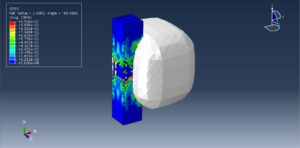

The Jones-Wilkins-Lee material model was selected to model the explosive material. The Jones-Wilkins-Lee (or JWL) equation of state models the pressure generated by releasing chemical energy in an explosive. This model is implemented in a form referred to as a programmed burn, which means that the reaction and initiation of the explosive are not determined by shock in the material. Instead, the initiation time is determined by a geometric construction using the detonation wave speed and the distance of the material point from the detonation points.

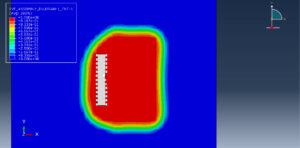

To model concrete behavior under severe load, Abaqus recommends some material models, here the Concrete Damaged Plasticity model with strain damage behavior is selected. The model is a continuum, plasticity-based, damage model for concrete. It assumes that the main two failure mechanisms are tensile cracking and compressive crushing of the concrete material

To model X-shaped steel core and reinforcements, the Johnson-Cook hardening and dynamic damage are selected

Dynamic explicit steps and general contact capability to consider all contact in the contact domain are considered. The proper boundary and initial conditions are assigned to all parts. The mesh should be fine to obtain the correct results

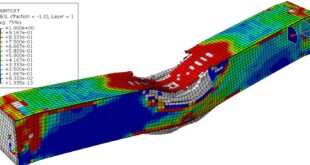

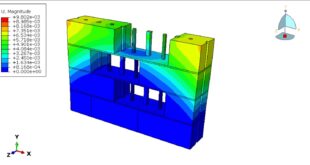

After the simulation, all results such as stress, tensile and compression damage of concrete, concrete damage and failure, X-shaped core damage and deformation TNT wave propagation, and others are available. You can see some figures for the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials