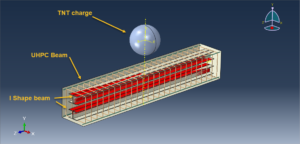

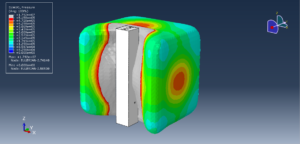

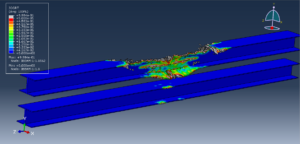

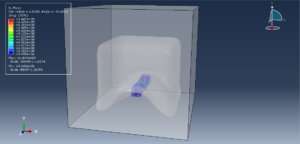

In this tutorial, the Simulation CEL explosion of steel-UHPC composite RC beam(column) with multiple encased steel profiles in Abaqus has been done. The Ultra-High-Performance-Concrete is modeled as a three-dimensional solid part. The bar and strip are modeled as three-dimensional wire parts. The steel beam core and TNT part are modeled as solid shape, and the domain as an Eulerian part. You can see a figuer of the assembled parts below

The past decade has witnessed frequent occurrences of localized wars and terrorist attacks. Some important infrastructure such as government buildings, and embassy buildings might be targets for a terrorist bombing attack. Understanding structural response to explosive loads is essential to protect critical infrastructure against explosions. Damage assessment of RC beam has been an active research field for many years due to RC beam being the primary connection and the force transmission in building structures.The damage assessment of RC members is a complicated problem. RC beams will manifest cracks, crushing, and spalling under explosion. These phenomena are affected by various parameters, such as the number of main steel bars, permeability of concrete, stress waveform, detonation point, and air pressure, among others

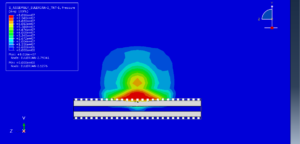

To model UHPC behaviour under severe load, the Johnson-Holmquist material method is selected. The model simulates the increase in strength shown by ceramics subjected to hydrostatic pressure as well as the reduction in strength shown by damaged ceramics. This is done by basing the model on two sets of curves that plot the yield stress against the pressure. To model TNT behaviour, The JWL equation of state is used.The Jones-Wilkins-Lee (JWL) equation of state (EoS) is commonly used in explosives modeling for describing the pressure-volume-energy relationship of detonation products. JWL EOS contains parameters describing relationships between volume, energy and pressure of detonation products. These parameters are determined by metal cylinder expansion test of detonation products. The chemical energy released during time interval is stored in the burnt products of the explosive itself. To model steel beams as core, the Johnson-Cook hardening and damage is considered. The elstic-plastic model is used for the steel bars and strips

Dynamic explicit step with a specific time is selected and that is so approariate for this type of analysis.Dynamic explicit is one of the most famous steps of Abaqus. it is originally developed for solving linear and nonlinear dynamic problems. The general contact with default property is applied to the contact domain. The steel bars and strips are embedded inside the UHPC beam. The proper boundary conditions are assigned to the beam and Eulerian domain. Both volumn fraction and uniform material method can be used to define the TNT volume and its location in the domain. The mesh should be fine to obtain correct results

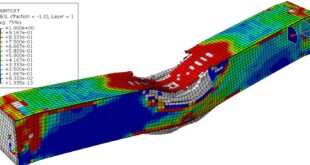

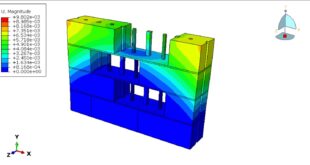

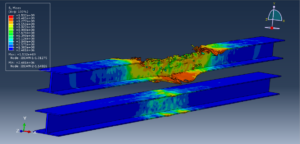

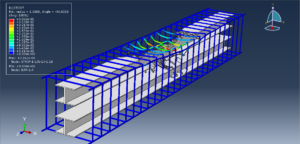

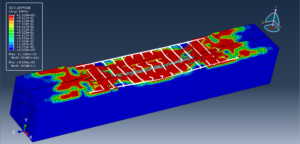

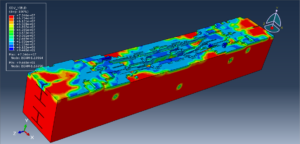

After the simulation, all resutls such as stress, strain, damage, failure, blast wave propagation,…are available. You can see some figures for the resutls below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-six Euros. you can click on the bellow bottom to begin the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials