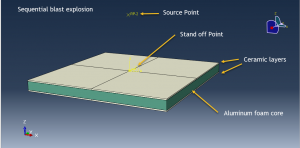

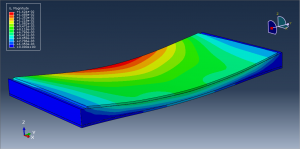

In this tutorial, the Simulation blast resistance of the composite slab(ceramic-Aluminum foam) under sequential explosion in Abaqus has been investigated. The two ceramic layers are modeled as three-dimensional solid part. The aluminum foam as a middle part is modeled as a three-dimensional solid part. You can see a figure of the assembled parts below

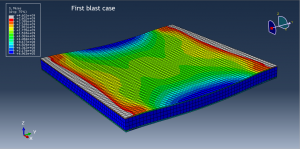

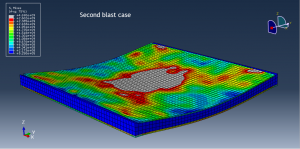

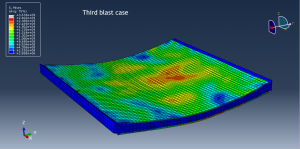

The aluminum foam is used to reduce the energy or absorb the blast energy by itself compression. To model aluminum foam or metal foam behavior, the Crushable foam material model is selected. To model ceramic behavior under severe load, the ductile damage criterion, Drucker-Prager plasticity, and equation of state are used. By using those material data, Abaqus can represent a good behavior of the ceramic. The dynamic explicit step in three separated simulation is used. In the first simulation, the analysis is done and the results are imported to the new or in the second simulation as an initial condition and the results of the second one also are imported to the third simulation. In all of the simulation, the amount and the location of the TNT is changeable. The ideal or perfect contact is assumed between ceramic and aluminum foam. The CONWEP air blast procedure is selected to model the TNT detonation in all three analysis. The fixed boundary condition is assigned to the all sides of the panel. The mesh should be fine to obtain correct results

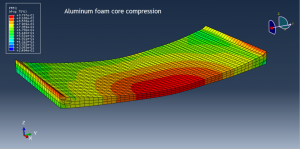

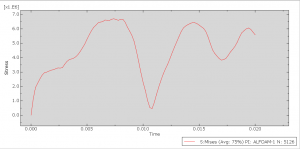

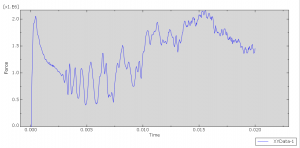

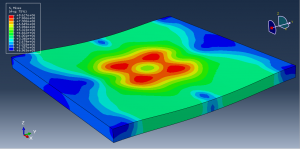

After the all simulation, the results such as stress, strain, damage, failure, displacement, and …are available. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials