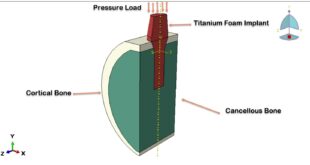

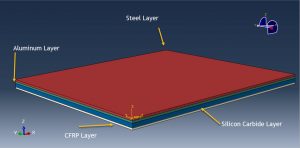

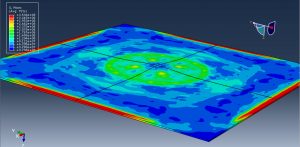

In this tutorial, the Simulation blast explosion over the composite panel(Steel-Aluminum-Ceramic-CFRP) in Abaqus has been investigated. The steel and aluminum plates are modeled as three-dimensional solid part. The silicon carbide or ceramic is modeled as a three-dimensional solid part. The CFRP is modeled as a three-dimensional solid part with four layers. You can see a figure of the assembled parts below

The study of blast load, known as blast or explosion dynamics or terminal ballistics has many crucial applications. An in-depth understanding of deformation behavior of materials under blast loading helps not only in designing better products but more importantly saving human life. Knowledge of material response under blast loading will help in estimating, enhancing and extending life and performance of any structure

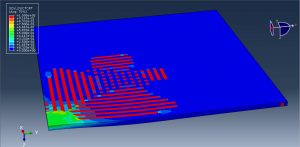

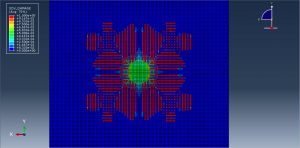

The response of metals to applied loading not only depends on strain but also on other parameters such as temperature, pressure, strain rate etc. To model steel and aluminum behavior under blast load, Johnson-Cook plasticity and damage model is used. The Johnson Cook (JC) model is a phenomenological model commonly used to predict the material response of metals subjected to high strain rate and impact loading. To model CFRP behavior elastic model as lamina and Hashin’s damage criterion is selected. To model ceramic behavior under impact or severe blast load, Abaqus recommends some material models that they are available in Abaqus CAE or through a code

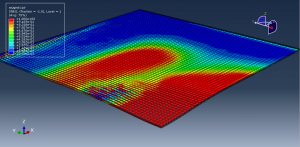

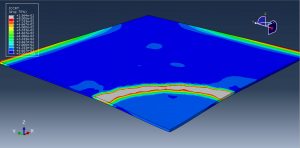

The dynamic explicit step is appropriate for this type of analysis and the mass scale technique is used to reduce the time of the simulation and create a stability in the model. The perfect contact model is used to define interaction among the surfaces of the parts. The CONWEP blast load procedure is selected to define blast load condition. The symmetry boundary is assigned to the symmetry zones and fixed boundary to the other sides. The mesh should be fine to obtain correct results

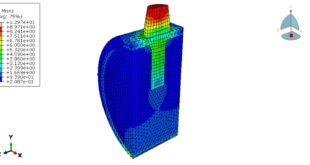

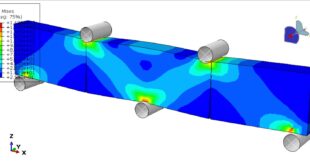

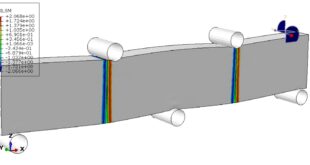

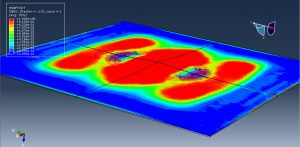

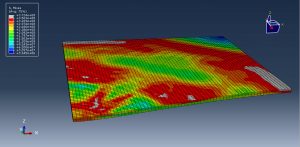

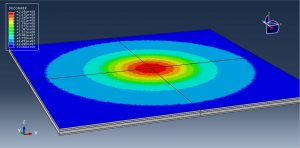

After the simulation, all results such as stress, strain, failure, damage, and… are available. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Eight Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials