Insulated concrete sandwich panels are comprised of two outer concrete wythes and an inner layer of foam insulation. They have been increasingly used because of their advantages of light weight and energy efficiency. Various shear connectors can be used to connect the two outer concrete wythes. More

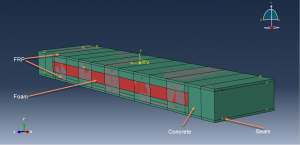

recently, Fiber-Reinforced Polymer (FRP) shear connectors have been used, which can eliminate thermal bridging and improve the thermal performance.insulated concrete sandwich panels are comprised of two layers of concrete, known as wythes, separated by a layer of rigid foam plastic insulation. The two wythes are connected by some form of shear transferring mechanism, generally using solid concrete web zones, metal connectors, plastic connectors, or a combination of these elements. The panels can provide dual function of transferring load and insulating the structure among other desirable characteristics of normal concrete panels, such as durability.You can see a figure of the assemble parts at below

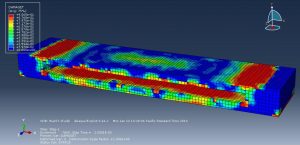

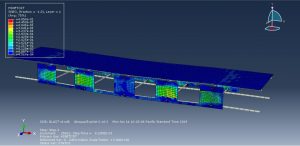

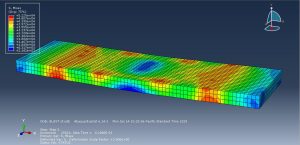

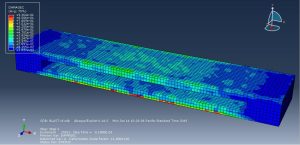

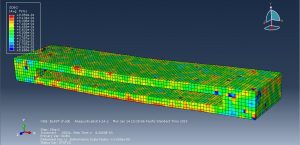

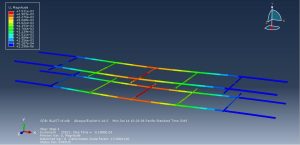

To model concrete and foam solid part, frontal and shear FRP shell part and to model beams wire part are used. CDP model for concrete,crushable foam for foam,Johnson-Cook plasticity for beam and Hashin’s damage for composite are used. Dynamic Explicit procedure is appropriate for this type of analysis. The contact between concrete-FRP and concrete-foam are considered as ideal and CONWEP interaction has used to model blast wave distribution .During the process tensile and compressive damage, foam compression and composite damage are obvious. You can see some figures of the results of this simulation

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials