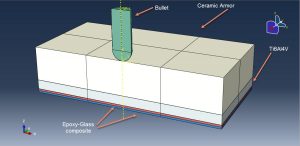

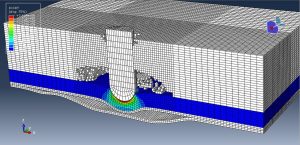

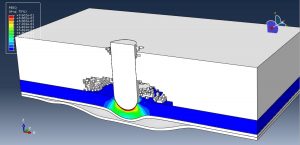

In this tutorial, the Simulation ballistic impact on the ceramic-titanium-composite armor in Abaqus has been studied. The ceramic, titanium and composite layers are modeled as a three-dimensional solid part. The bullet is modeled as a three-dimensional solid part. You can see a figure of the assembled parts at below

The use of lightweight armor systems against ballistic threats is of significance to the development of military weapons owing to providing the high ballistic protection level and simultaneously increasing the mobility of tanks and other military aircraft. Previously, the widely accepted high hardness steel appears to be potential armor architectures, which provides a sufficiently high ballistic performance. However, it does not improve significantly the structural weight. As the armored technique develops in current years, a new type of armor system made of a hard ceramic front plate and energy-absorbing metal or high tensile strength fibers layer is widely used to defeat armor-piercing projectiles. The front ceramic plate blunts and shatters the impacting projectile, and the back laminate materials absorb the remaining kinetic energy of the projectile and simultaneously support the ceramic and projectile fragments to prevent them from further damage

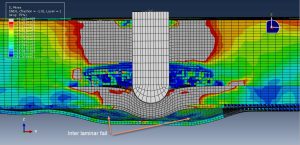

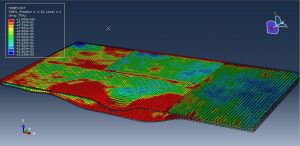

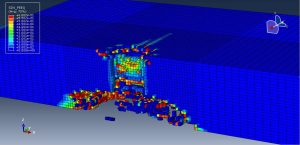

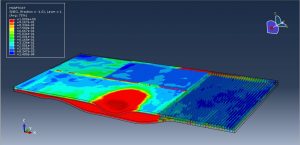

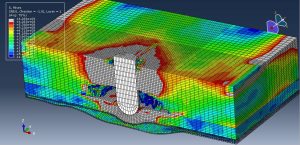

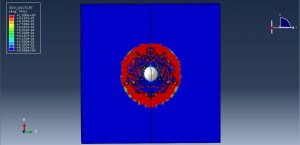

To model ceramic behavior under the high-velocity impact, the Johnson-Holmquist model is used. To model the titanium behavior the Johnson-Cook plasticity and damage are used to predict the damage zone under the impact. For the epoxy-glass fiber elastic behavior as lamina type with failure stress and Hashin’s damage criterion with evolution is used to consider fiber damage during the impact. The dynamic explicit procedure is appropriate for this type of analysis. The general contact procedure with friction coefficient is used to model contact between all parts and between to composite layers damage and cohesive behavior is used to model the separation during the simulation. The contact among the other parts is assumed as perfect contact. The proper boundary conditions are assigned to the target parts and initial velocity to the bullet. The mesh should be fine at the contact zone to have a good performance during the impact

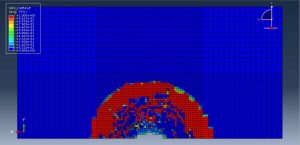

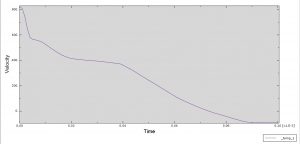

After the simulation, damage for ceramic, titanium, and composite layers is obvious. The ceramic layer absorbs the initial velocity of the bullet and reduces it to half. The titanium and composite layers are absord the bullet energy and the velocity of bullet be zero at the end of the simulation. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Thirty Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials