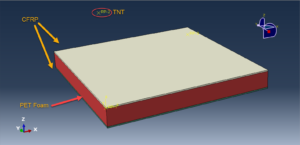

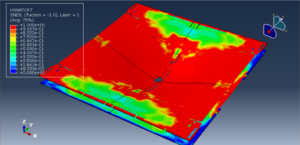

In this tutorial, the Simulation air blast load over CFRP facings and PET foam core panel in Abaqus has been investigated. The CFRP sheets are modeled as three-dimensional parts with sixteen layers, and the Polyethylene terephthalate(PET) foam is modeled as a three-dimensional solid part. You can see a figure of the assembled parts below

The appropriate choice of material model, being suitable for the description of stress-strain relation in a foam is important. However, various foams have extremely different properties, thus the task is not so simple and each type of foam needs to be carefully analyzed. Usually, experimental identification of the material properties of the foam is done. Procedures exist, according to ISO or ASTM standards, that enable the determination of the core’s elastic and strength properties, which are also valid for PET foams. Moreover, technical data sheets are provided for foams that are available on the market, which include information on the most important material properties declared by producers and identified according to the aforementioned standards. In such a case it seems that the description of material behavior should be easier. Nevertheless, the standards give recommendations that can be helpful only when the elastic response of the core is considered. What is more, the fact that the foam can be generally anisotropic is not commented on. For these reasons, some difficulties can be encountered when detailed analyses of sandwich response are done and identification of the foam core materials properties according to standards seems to be insufficient in such a situation

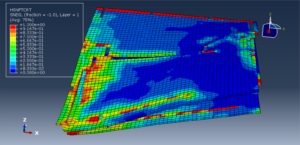

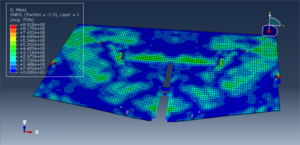

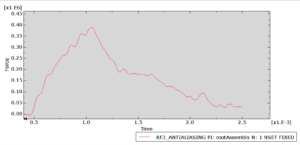

To model CFRP failure under severe blast load, the elastic model and damage behavior are considered. The foam is modeled as an elastic with crushable foam modeled as plastic hardening. The dynamic explicit step is appropriate for this type of simulation. Proper interactions and boundaries are assigned to all parts. The CONWEP air blast load procedure is selected to define the explosion

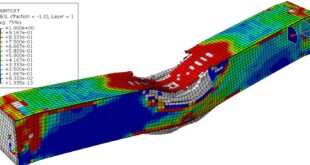

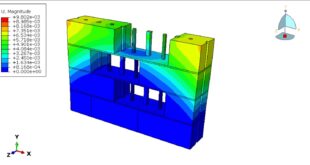

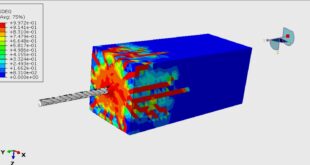

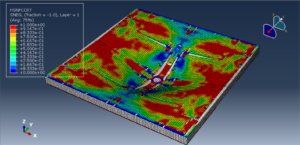

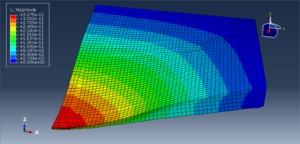

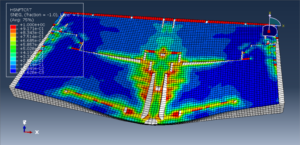

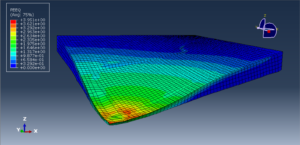

After the simulation, all results such as stress, strain, CFRP damage, foam compression, and others are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials