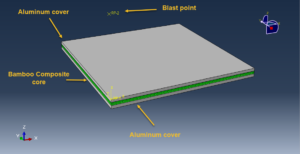

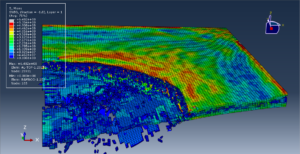

In this tutorial, the Simulation air blast load over a composite panel(Aluminum+bamboo fiber) in Abaqus has been investigated. Because of the symmetry circumstance, one quarter of the geometries are modeled. The aluminum plates are modeled as three-dimensional solid part. The bamboo plate as a core of the composite panel is modeled as three-dimensional shell part with sixteen layers. You can see a figure of the assembled parts bwlo

Existent numerical models used for blast simulation can be roughly divided into two groups: the empirical model for blast pressure approximation and the numerical model based on the Lagrange/Euler method. For the empirical blast pressure model, the CONWEP air blast function was developed [1] for blast overpressure determination under certain conditions: the free air detonation of a spherical charge and the surface detonation of a hemispherical charge. While the surface detonation approaches the conditions of a mine blast, anti-vehicular mines are most commonly buried anywhere. Contemporary world is facing numerous bomb explosion attacks on public and civil buildings causing huge loss of property and human lives. As a consequence, the society needs more safety and protection for the existing structures against blast loads. The composite panels with the great resistance against the blast load are widely used as a protection system

To model aluminum behavior under high-velocity impact, the Johnson-Cook plasticity model is selected. The Johnson-Cook plasticity model is a particular type of Mises plasticity model with analytical forms of the hardening law and rate dependence, and suitable for high-strain-rate deformation of many materials, including most metals. To consider the damage which happens during the analysis, the Jonson-Cook damage model is used also

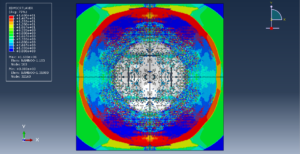

Damage initiation refers to the onset of degradation at a material point. In ABAQUS the damage initiation criteria for fiber reinforced composites are based on Hashin’s theory. These criteria consider four different damage initiation mechanisms: fiber tension, fiber compression, matrix tension, and matrix compression. For the Bamboo member, sixteen layers with different oreintation of the fiber is considered

Dynamic explicit step is so appropriate for this type of analysis. A general contact algorithm (Explicit) accessible in the Abaqus/Explicit interaction type is used in this analysis to define the contact between components. The cohesive contact method between the aluminum plates and bamboo is considered by using stiffness in three directions, damage, and fracture energy. The CONWEP blast method is selected by using the mass of the TNT and its distance from the the frontal surface of the composite panel. The symmetry boundary conditions are assigned to the symmetry zones. The mesh should be find to obtain the coorect results

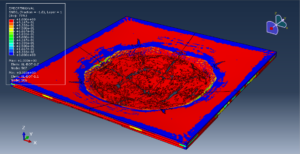

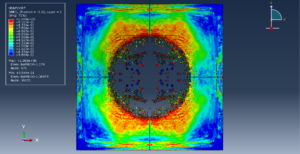

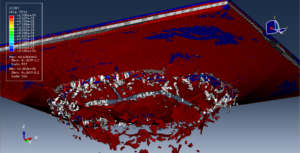

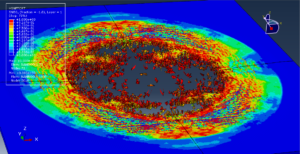

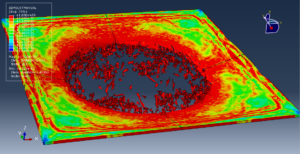

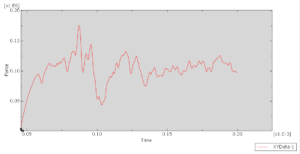

After the simulation, all results such as stress, strain, damage, failure, fiber damage are available. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-six Euros. you can click on the bellow bottom to begin the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials