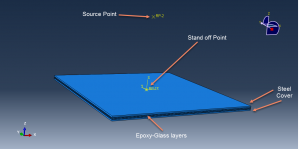

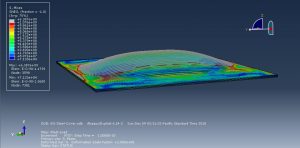

In this video Simulation air blast explosion over sandwich plate(steel-Epoxy glass) in Abaqus has been investigated.In this example two steel plates as solid part with four epoxy glass layers as continuum shell part are used . Composite section is placed inside two steel plates. You can see a schematic and position of these part at below

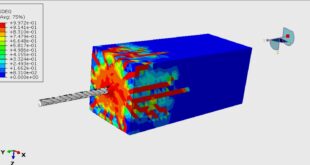

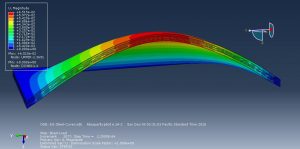

To model correct behavior of the steel plates under blast load and huge deformation, Johnson-Cook plasticity and damage with evolution and to model composite Hashin’s damage criterion has been implanted. These two material model with their equations are defined and discussed. According to the blast procedure with dynamic nature, dynamic explicit step has been used to model sudden load and rapid deformation.

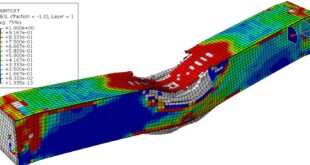

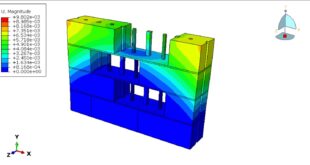

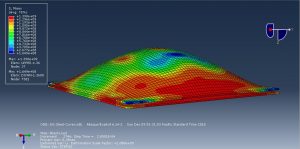

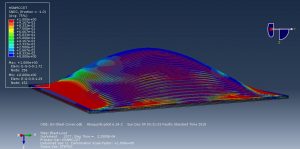

To model blast behavior CONWEP technique in interaction modulus with incident wave property as air blast with 1 and 2 kg TNT are tested.There are two way to model behavior between steel-composite and composite-composite plates ,the first way is using tie contact to simplify the problem and the second way define surface to surface contact with damage,cohesive,geometry,contact stiffness and friction as contact property. In this example tie constraint is used.During the analysis all members have large deformation and steel plate receive a huge amount of TNT pressure and this matter causes a high Von Misses stress. The hashin’s damage output shows damaged area and you can see some results as figure at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-One Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials