Introduction to Polymeric and Metal Foam Simulation in Abaqus

Polymeric and metal foam are advanced materials widely used in industries such as aerospace, automotive, biomedical, and construction due to their unique properties, including high strength-to-weight ratios, energy absorption, and thermal and acoustic insulation. Simulating these materials in Abaqus, a powerful finite element analysis (FEA) software, allows engineers and researchers to predict their mechanical, thermal, and dynamic behavior under various loading conditions.

Key Characteristics of Polymeric and Metal Foam

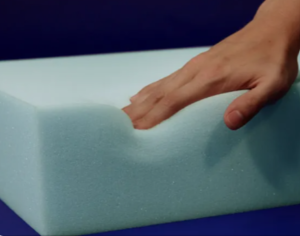

Polymeric Foam

Lightweight and flexible

Excellent energy absorption and damping properties

Used in packaging, cushioning, and insulation applications

Examples: Polyurethane (PU), polystyrene (PS), and polyethylene (PE) foams

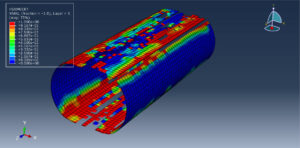

Metal Foam

High strength and stiffness relative to their density

Good thermal and electrical conductivity

Used in lightweight structural components, energy absorbers, and heat exchangers

Examples: Aluminum, titanium, and nickel foams

Challenges in Foam Simulation

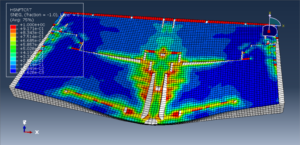

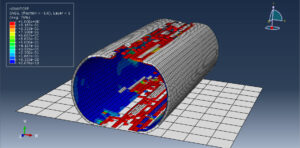

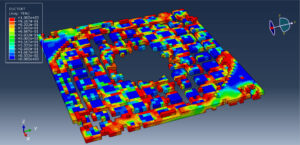

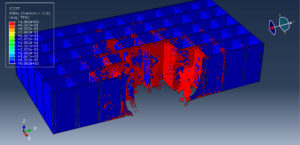

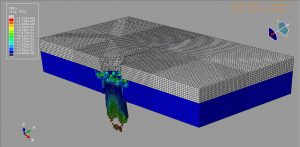

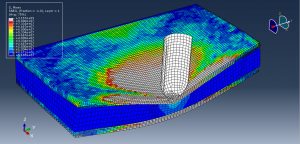

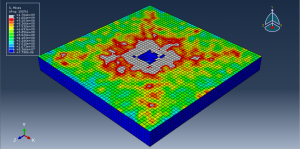

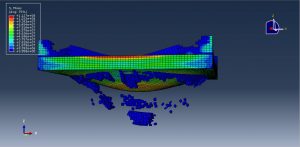

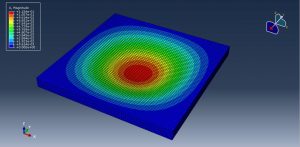

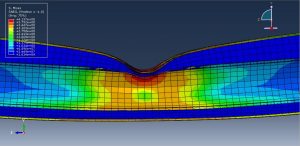

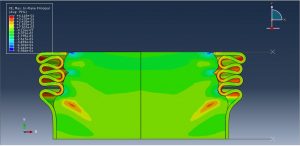

Complex Microstructure: Foams have a porous, heterogeneous structure that makes their mechanical behavior highly nonlinear

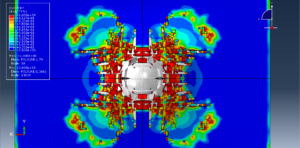

Anisotropy: The mechanical properties of foams can vary with direction due to their cellular structure

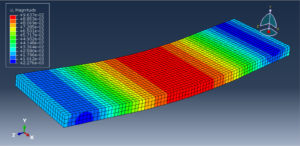

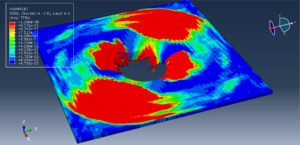

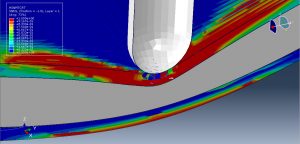

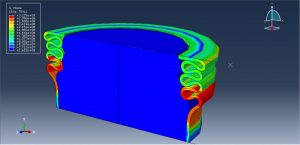

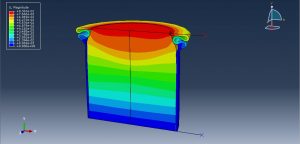

Large Deformations: Foams often undergo significant deformations under compression, requiring accurate modeling of nonlinear material behavior

Energy Absorption: Capturing the energy dissipation mechanisms during impact or compression is critical for accurate simulation

Material Models

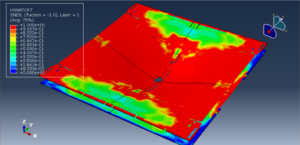

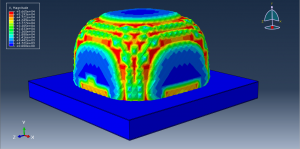

Crushable Foam Model: Suitable for modeling the compressive behavior of foams, including plastic deformation and densification

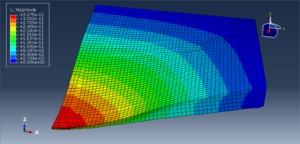

Hyperelastic Models: Used for polymeric foams undergoing large elastic deformations

Viscoelastic Models: Capture time-dependent behavior, such as creep and stress relaxation, in polymeric foams

Plasticity Models: For metal foams, including isotropic and anisotropic hardening

Applications of Foam Simulation in Abaqus

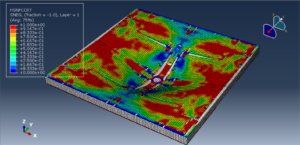

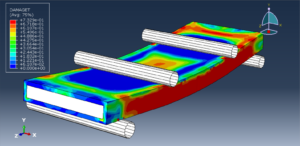

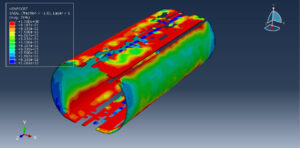

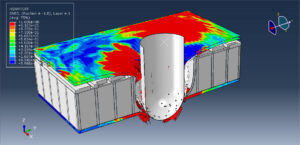

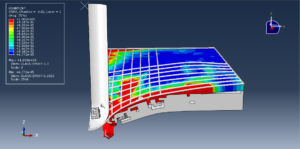

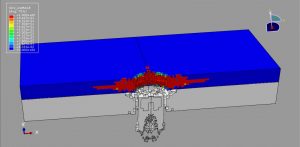

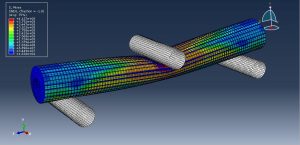

Crashworthiness Studies: Simulating the energy absorption of foams in automotive and aerospace components

Structural Optimization: Designing lightweight foam-filled structures for improved performance

Thermal Management: Analyzing heat dissipation in metal foam heat exchangers

Biomedical Implants: Studying the mechanical behavior of polymeric foams used in prosthetics or tissue engineering

Simulating polymeric and metal foams in Abaqus enables engineers to understand and optimize their performance in various applications. By leveraging Abaqus’s advanced material models, element types, and analysis capabilities, accurate predictions of foam behavior can be achieved, leading to innovative designs and improved product performance

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials