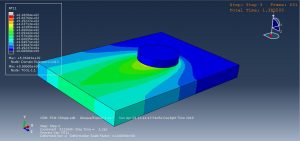

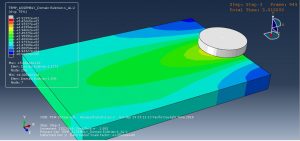

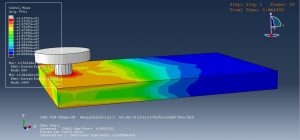

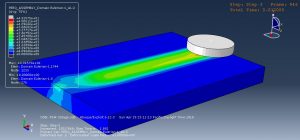

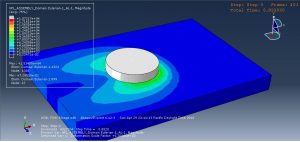

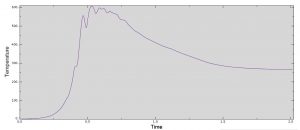

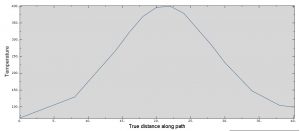

Friction Stir Welding (FSW) is a solid state joining process that relies on frictional heating and plastic deformation realized at the interaction between a non-consumable welding tool that rotates on the contact surfaces of the combined parts. The experiments are often time consuming and costly. To overcome these problems, numerical analysis has frequently been used in last years. Several simplified numerical models were designed to elucidate various aspects of the complex thermo-mechanical phenomena associated with FSW. This video investigates a thermo-mechanical finite element model based on Coupled Eulerian Lagrangian method to simulate the friction stir welding of the AA 6082-T6 alloy. Abaqus/cae software is used in order to simulate the welding stage of the Friction Stir Welding process. This video presents the steps of the numerical simulation using the finite elements method, in order to evaluate the boundary conditions of the model and the geometry of the tools by using the Coupled Eulerian Lagrangian method. During the simulation rotation of tool causes a huge amount of heat and increased aluminium temperature. This simulation made by three steps and dynamic temp explicit has been applied. You can see some figures of this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Seven Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials