In this tutorial Numerical simulation of Electro-Hydraulic forming process by using acoustic method in Abaqus has been verified base on the ISI paper.

Electro-hydraulic forming is one of the methods that highly considered among automotive specialists. This method is known as “high strain rate forming” method. In this process, an electrical discharge within a liquid medium transforms the electrical energy into a mechanical energy.Severe discharge of electrical energy creates a plasma channel that leads to evaporation of the water between two electrodes and generates a high-speed shock wave propagating towards the work-piece. Thus, the sheet moves into the die cavity and reaches its desired shape. Carrying the force by the liquid medium, the need for a punch is revoked. Compared with electro-magnetic forming, this process can form versatile metals due to its non-sensitivity to conduction

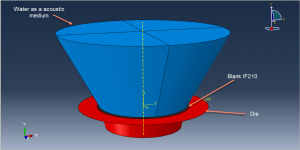

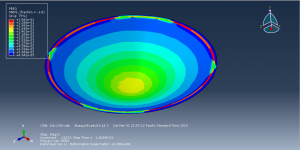

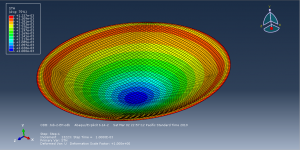

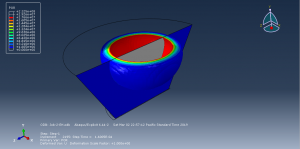

In this tutorial water and blank are modeled as three dimensional part. The elastic plastic(Johnson-Cook base on the paper) for metal plate has been used.You can see a figure of assembled part at below

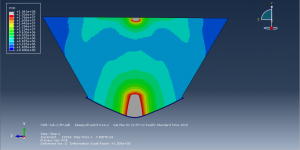

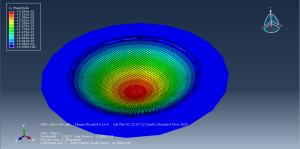

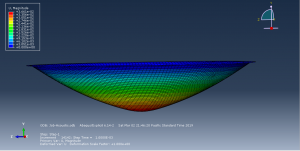

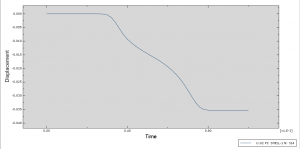

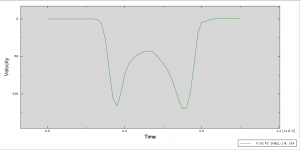

Dynamic explicit procedure is appropriate for this type of analysis.Surface to surface contact between die and blank,and tie constraint between blank and water are used.The acoustic interaction has assigned to the water part.The acoustic boundary for water and fix condition for die are considered. During the simulation maximum displacement, stress and strain can be achieved. The maximum displacement of dome has verified and the value which achieved from the simulation would be equal with paper value.You can see some figures of this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Seven Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials