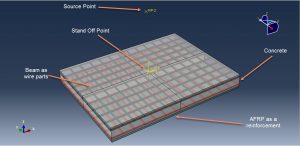

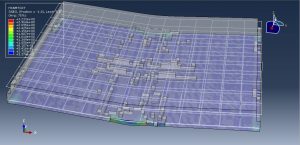

In this tutorial, numerical simulation of blast resistance of RC slab strengthened with AFRP in Abaqus-Damage investigation- has been studied. The concrete slab is modeled as a three-dimensional solid part, the AFRP is modeled as four layers composite with shell part and the embedded beam inside the concrete host is modeled as a wire part. You can see a figure of the assembled parts at below

Due to the increase of terrorist attacks and accidental explosion in current society, the RC structure, which is the principal construction of civilian buildings and military construction, tends to exposed to blast loadings. The short-duration and high magnitude of blast loading can induce severe damage to the RC structure. Generally, it’s known that concrete has a relatively high capacity to resist the blast loads. In recent decades, the external bonding of fiber-reinforced polymer (FRP) strips to improve the blast resistance has received great interest. The technique of external bonding FRP has many advantages, such as high strength, lightweight, lower cost, excellent corrosion resistance, convenient construction, etc. Aramid Fiber Reinforced Plastic (AFRP) is a relative newcomer to FRP composites, compared with CFRP and GFRP. Although besides the common properties of all the FRP materials, it has some other unique features such as superior dielectric properties, high heat and flame resistance, better corrosion, impact and fatigue resistance, short curing time, etc

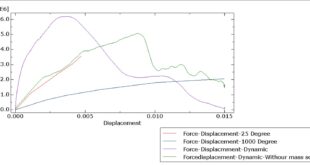

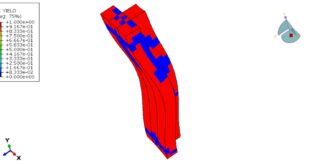

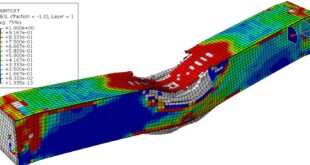

To model steel behavior elastic and Johnson-Cook plasticity and damage data were used. The AFRP is modeled as lamina with Hashin’s damage criterion. To model concrete behavior under massive pressure like detonation, the JH2 material model instead of CDP or Brittle cracking was used. The JH2 model can predict damage propagation in good order and the result for that is reliable. The dynamic explicit step is appropriate for this type of analysis. The beam is used as an embedded region inside the concrete. The CONWEP blast load procedure is used to define the TNT explosion near the concrete slab. To define concrete-AFRP interaction, cohesive surface behavior with damage data is used. The fixed boundary condition is applied to the slab. The mesh has a good effect on the results, so it needs to use a fine mesh

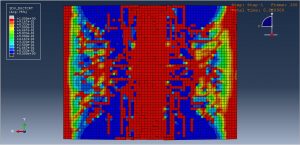

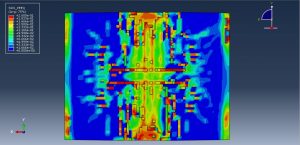

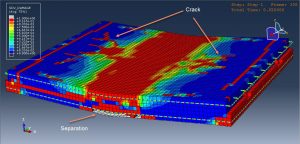

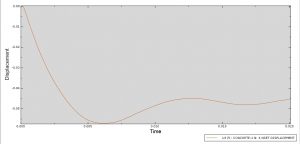

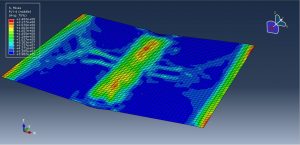

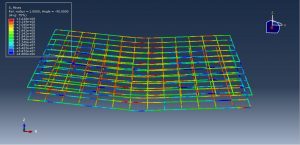

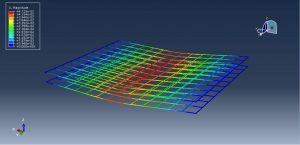

After the simulation, all results such as damage, stress, strain, failure zone ….can be obtainable. You can see some figures for the result below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Thirty-One Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials