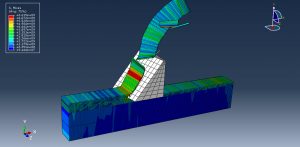

Forming Simulation and Analysis in Abaqus

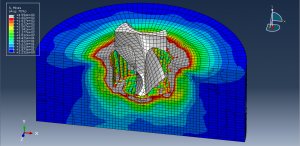

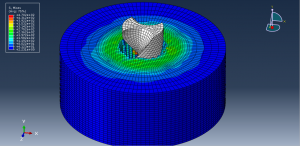

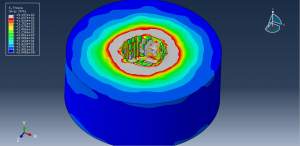

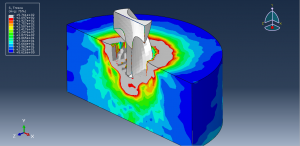

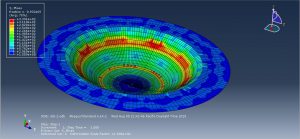

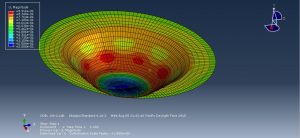

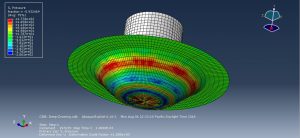

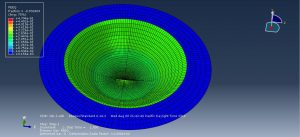

Forming simulation and analysis in Abaqus is a powerful tool used to model and predict the behavior of materials during manufacturing processes such as stamping, forging, rolling, and extrusion. Abaqus, a leading finite element analysis (FEA) software, provides advanced capabilities to simulate complex forming processes, enabling engineers to optimize designs, reduce material waste, and improve product quality. Metal forming is a critical manufacturing process that shapes metal workpieces into desired geometries through plastic deformation. Abaqus, a leading finite element analysis (FEA) software, is widely used to simulate and analyze metal-forming processes. These simulations help engineers predict material behavior, optimize tooling, reduce defects, and improve the overall efficiency of the manufacturing process

Features of Forming Simulation in Abaqus

Material Modeling

Abaqus supports a wide range of material models, including elastic-plastic, hyperelastic, and viscoplastic materials. This allows for an accurate representation of material behavior under different forming conditions

Users can define material properties such as yield strength, hardening behavior, and anisotropy, which are critical for realistic simulations

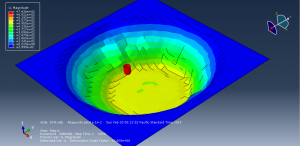

Contact and Friction

The software includes robust contact algorithms to model interactions between the workpiece and the tooling. This is essential for capturing the effects of friction and lubrication during forming

Friction models such as Coulomb friction and shear friction can be applied to simulate realistic contact conditions

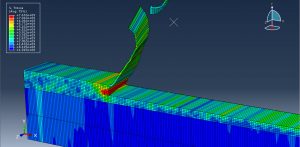

Large Deformation and Nonlinearity

Forming processes often involve large deformations and nonlinear material behavior. Abaqus excels in handling these complexities through its nonlinear solver capabilities

The software can account for geometric nonlinearities, material nonlinearities, and contact nonlinearities, ensuring accurate simulation results

Key Metal Forming Processes Simulated in Abaqus

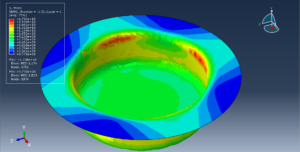

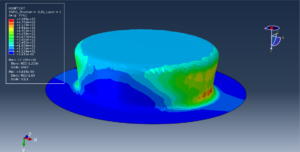

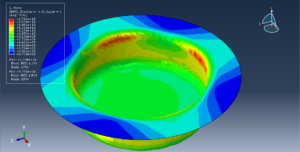

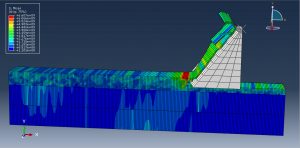

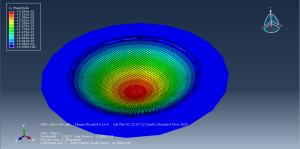

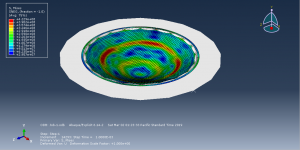

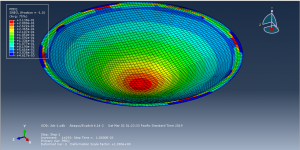

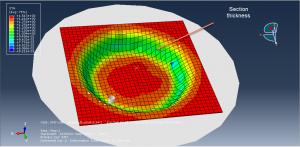

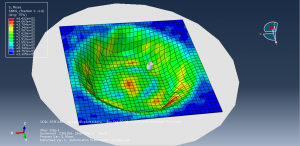

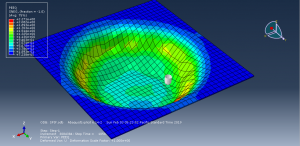

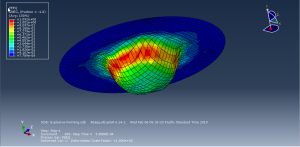

Stamping

Used in the automotive and aerospace industries to form sheet metal into complex shapes

Abaqus can simulate deep drawing, bending, and stretching processes, including spring back analysis

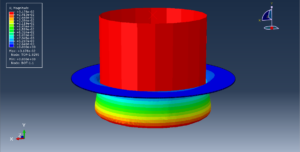

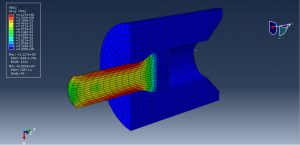

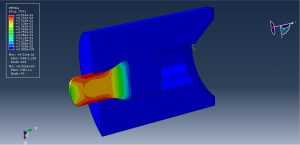

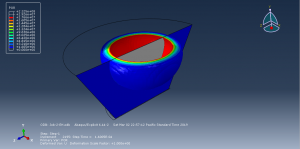

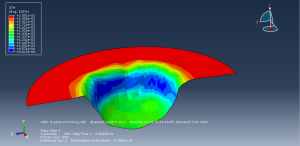

Forging

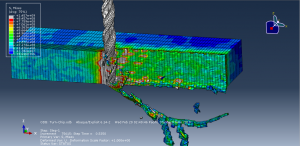

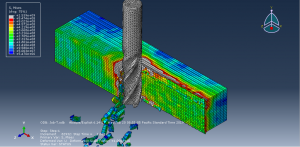

Involves shaping metal using compressive forces, often at high temperatures

Abaqus can model open-die and closed-die forging processes, including material flow and die-filling

Rolling

A process where metal is passed through rollers to reduce thickness or achieve specific cross-sections

Abaqus can simulate both hot and cold rolling processes, including roll deflection and material hardening

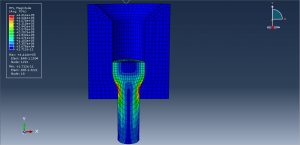

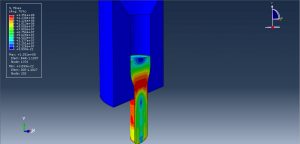

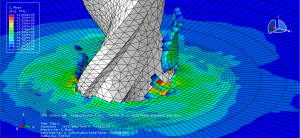

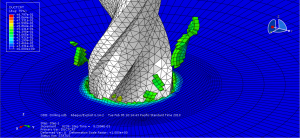

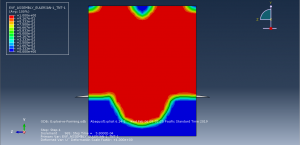

Extrusion

Pushing metal through a die to create long products with a constant cross-section

Abaqus can model direct and indirect extrusion processes, including material flow and die wear

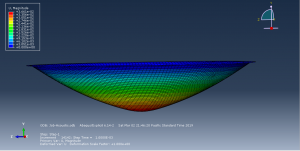

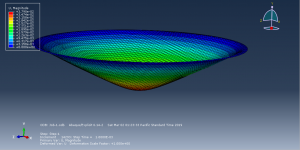

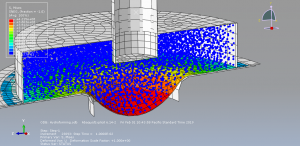

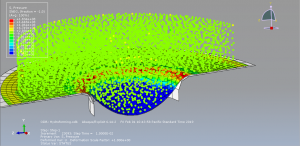

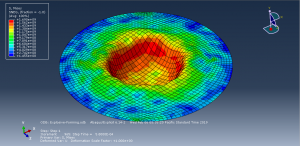

Hydroforming

Uses fluid pressure to form metal into complex shapes

Abaqus can simulate tube hydroforming and sheet hydroforming, including fluid-structure interaction

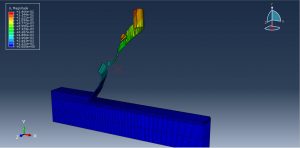

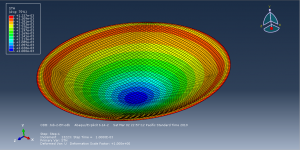

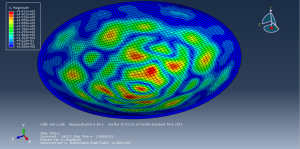

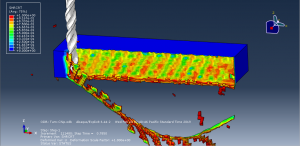

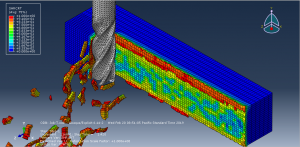

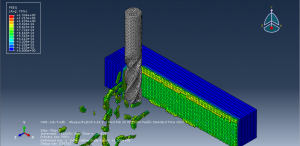

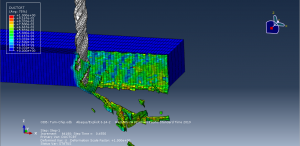

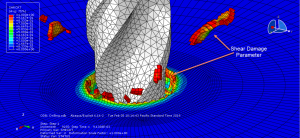

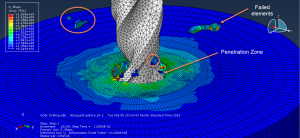

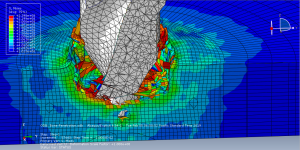

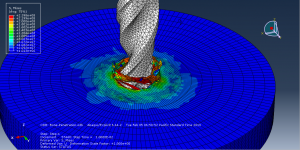

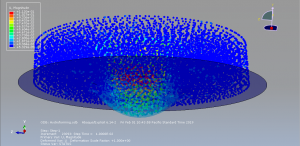

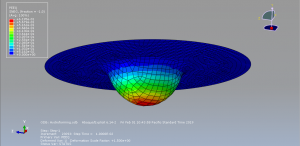

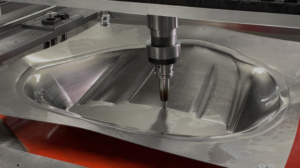

Incremental Forming

A flexible process where a tool incrementally deforms a sheet metal workpiece

Abaqus can model the progressive deformation and predict forming limits

Applications of Forming Simulation in Abaqus

Automotive Industry: Simulating stamping processes for car body panels to ensure proper fit and finish

Aerospace Industry: Modeling the forming of complex aerospace components to meet stringent quality standards

Consumer Goods: Optimizing the design of household appliances and electronics for manufacturability

Metalworking: Analyzing forging and extrusion processes to improve material utilization and reduce defects

Benefits of Using Abaqus for Forming Simulation

Reduced Prototyping Costs: By simulating forming processes, engineers can identify potential issues early in the design phase, reducing the need for physical prototypes

Improved Product Quality: Accurate simulations help in predicting and mitigating defects such as wrinkling, tearing, and spring back

Enhanced Process Efficiency: Optimization of forming parameters leads to reduced material waste and shorter production cycles

Innovative Design Exploration: Engineers can explore new designs and materials with confidence, knowing that the forming process can be accurately simulated

In summary, forming simulation and analysis in Abaqus is an essential tool for modern manufacturing, providing insights that drive innovation, efficiency, and quality in product development.

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials