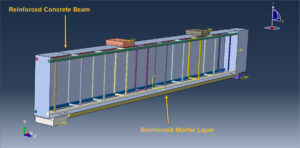

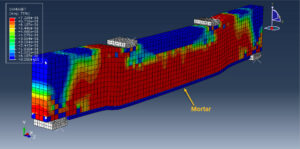

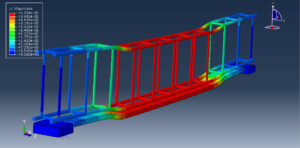

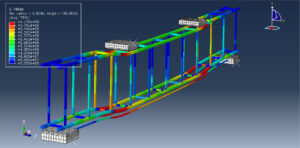

In this tutorial, the Flexural response and load capacity of reinforced concrete beam strengthened with reinforced mortar layer in Abaqus has been studied. The concrete and mortar are modeled as three-dimensional solid parts. The steel reinforcements are modeled as wire parts. You can see a figure of the assembled parts below

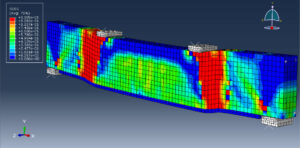

The rehabilitation and strengthening of concrete structures are important objectives in civil engineering. In recent decades, many approaches to repair and reinforced concrete (RC) beams have been established, such as externally bonded (EB), near-surface-mounted (NSM), textile-reinforced mortar (TRM), and the use of ultra-high-performance concrete (UHPC) layer (with or without reinforcement). The load-bearing capacity of the beam and crack control were enhanced using a highly ductile concrete layer. Conversely, the strengthened beams could no longer sustain the inelastic deformation before failure. Moreover, microcracks present in the strengthening layer under tensile stresses limit the ductility of the strengthened beam, causing premature rupture of the tensile reinforcement, specifically at low reinforcement ratios. Consequently, additional tensile reinforcement must be added to the strengthening layer to significantly enhance the flexural capacity of the beam. The reinforced mortar layer is a new way to increase the load capacity and concrete beam ductility

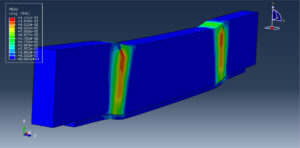

In this example, the Concrete Damaged Plasticity material model is selected to define the properties of the concrete beam and mortar layer. The elastic-plastic model is considered for all steel parts

The general static step with some changes in the convergence model is appropriate for this type of analysis. All interactions, and constrains are applied. The proper boundary, load, and meshes are assigned to all parts.

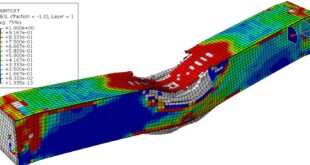

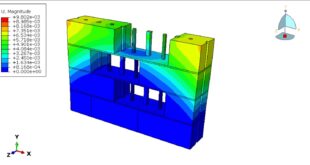

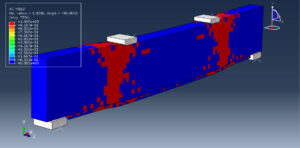

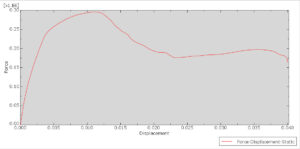

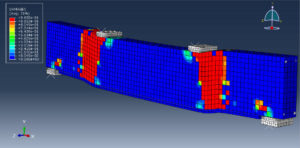

After the simulation, all results such as stress, strain, tension and compression damage, mortar layer failure, force-displacement diagram, and others are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials