In this simulation Finite Element simulation of Electro-Hydraulic Forming of Sheet by using time pressure curve in Abaqus has been investigated. Sheet metal forming processes are those in which force is applied to a piece of sheet metal to modify its geometry rather than remove any material. The applied force stresses the metal beyond its yield strength, causing the material to plastically deform, but not to fail. By doing so, the sheet can be bent or stretched into a variety of complex shapes. The conventional sheet metal forming processes include bending, roll forming, deep drawing and stretch forming. With advancement in the technology several high strain rate forming processes like explosive metal forming process, electro-magnetic pulse forming and electro-hydraulic forming processes which are based on high pressure pulse generation using different sources of energy are being used frequently in the industry

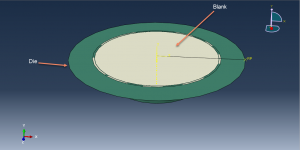

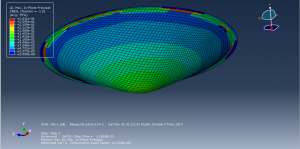

The blank is modeled as three dimensional shell part with elastic plastic material property.You can see a figure of assembled part at below

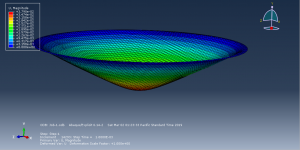

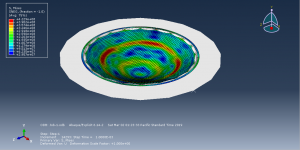

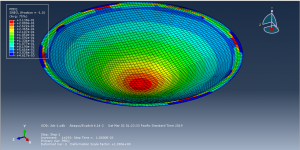

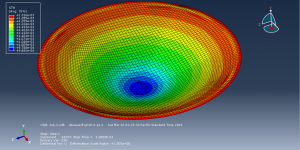

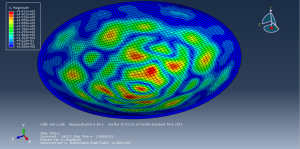

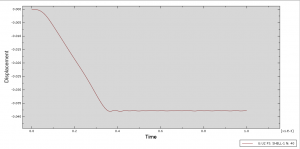

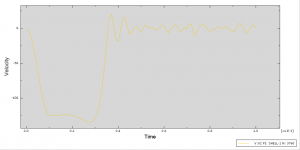

In this simulation the validation of the paper has done and the simulation has good appropriate with the paper. Dynamic explicit step with surface to surface contact has been used. Time-Pressure curve has use to model the pressure pulse . During the simulation the maximum displacement of dome is the same with paper result .You can see some figures of this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials