Fatigue and Cyclic Loading in Abaqus

Mechanical fatigue is a phenomenon where a material undergoes progressive and localized structural damage when subjected to cyclic or fluctuating stresses, even if these stresses are below the material’s ultimate tensile strength. Over time, this repeated loading and unloading can lead to the initiation and propagation of cracks, ultimately failing. Fatigue is a critical consideration in the design and maintenance of engineering components, particularly in industries such as aerospace, automotive, and civil engineering.

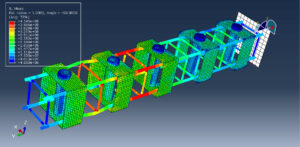

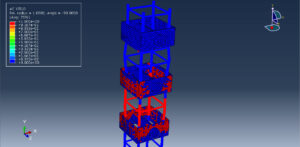

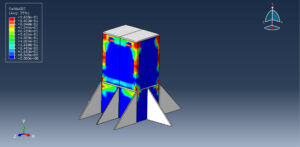

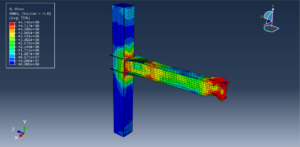

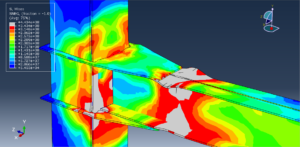

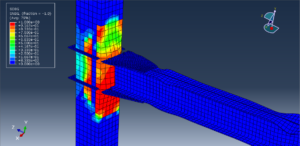

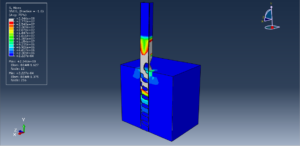

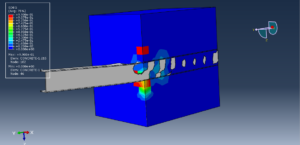

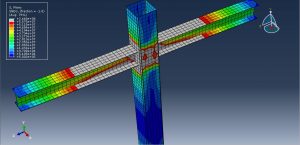

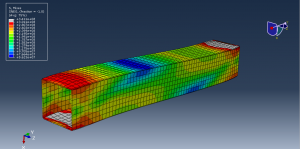

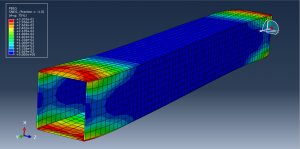

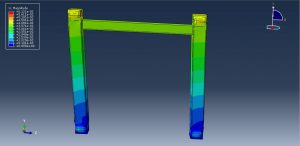

Fatigue analysis in Abaqus is a powerful tool for predicting the life of components subjected to cyclic loading. Abaqus, a finite element analysis (FEA) software, allows engineers to simulate the effects of repeated loading and unloading on materials and structures. This helps in identifying potential failure points and estimating the fatigue life of components.

Key Concepts in Abaqus Fatigue Analysis

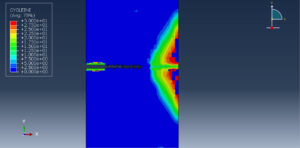

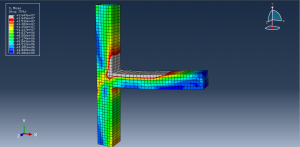

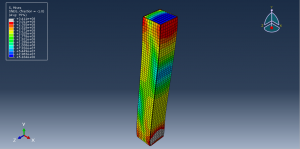

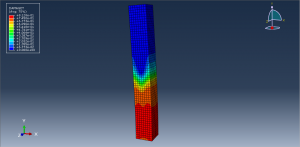

Cyclic Loading

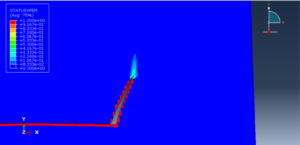

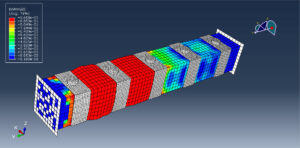

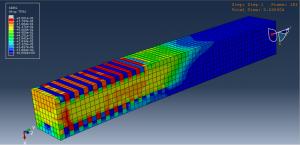

Cyclic loading refers to the repeated application of loads that vary with time. This can be sinusoidal, random, or any other form of periodic loading

In Abaqus, cyclic loading can be defined using amplitude curves that describe how the load varies over time

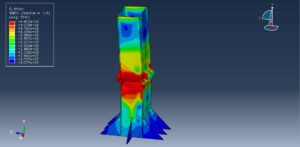

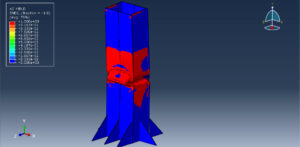

Fatigue Analysis

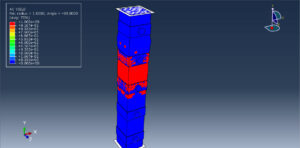

Fatigue analysis in Abaqus involves predicting the number of cycles a component can endure before failure occurs

Abaqus provides several methods for fatigue analysis, including stress-life (S-N), strain-life (ε-N), and fracture mechanics approaches

Fatigue Life

The number of stress cycles a material can endure before failure occurs

Determined through fatigue testing, such as the S-N curve (stress vs. number of cycles to failure)

Fatigue Limit

The maximum stress amplitude below which a material can theoretically endure an infinite number of cycles without failing

-

Not all materials have a fatigue limit (e.g., aluminum alloys do not, while some steels do)

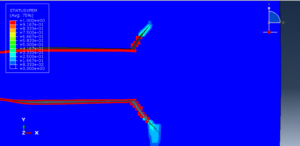

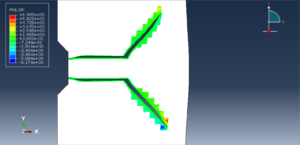

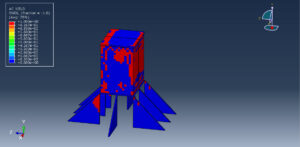

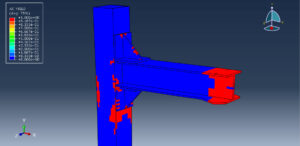

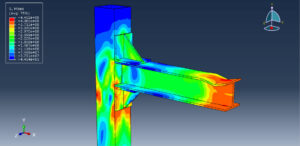

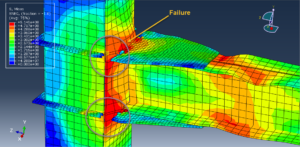

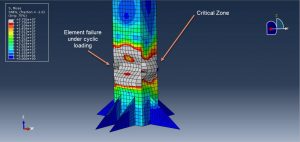

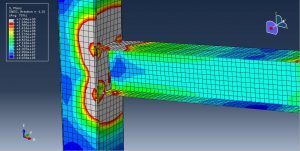

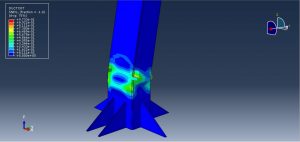

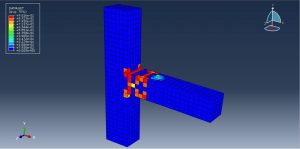

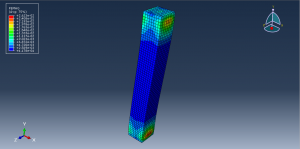

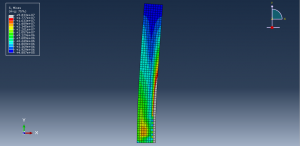

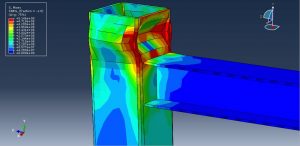

- Stress Concentration

- Localized areas of high stress, often due to geometric discontinuities (e.g., notches, holes, or sharp corners), which can initiate fatigue crack

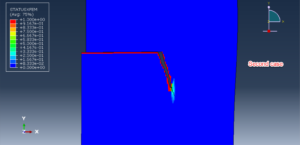

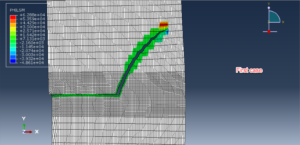

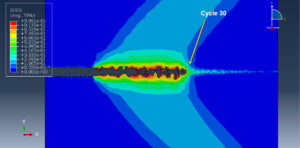

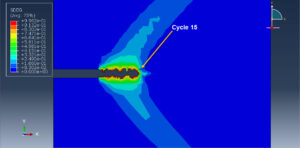

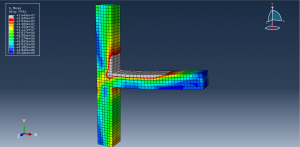

Crack Initiation and Propagation

Initiation: Microcracks form at stress concentrations or defects in the material

Propagation: Cracks grow incrementally with each stress cycle until critical crack size is reached, leading to sudden failure

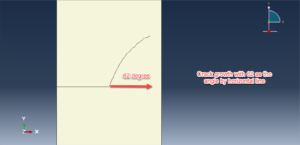

Fracture Mechanics Approach

Focuses on crack growth and propagation

Uses parameters like stress intensity factor (K) and crack growth rate (da/dN)

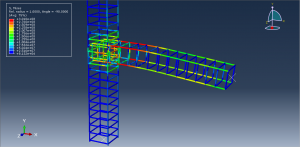

Applications of Fatigue Analysis in Abaqus

Aerospace: Predicting the fatigue life of aircraft components like wings and landing gear

Automotive: Analyzing the durability of suspension systems and engine part

Civil Engineering: Assessing the fatigue life of bridges and structures under dynamic loads

Manufacturing: Evaluating the lifespan of machinery and tools subjected to cyclic loading

By leveraging Abaqus for fatigue and cyclic loading analysis, engineers can gain valuable insights into the durability and reliability of their designs, ultimately leading to safer and more efficient products

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials