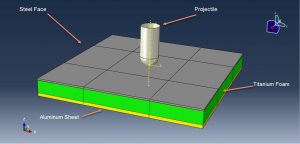

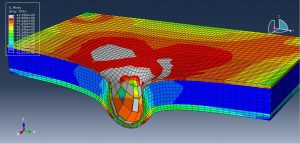

In this tutorial, the Dynamic response of square sandwich plates with a metal foam core subjected to rigid projectile impact in Abaqus has been investigated. The sandwich structure has been paid more attention and widely used in a number of critical engineering due to its excellent advantages over the monolithic solid structure of the same mass. The sandwich structure has been considered to be a promising alternative to the monolithic solid structure. The structural behavior of the sandwich structure depends on the material properties, the geometries of the face-sheet, the core and boundary conditions, etc. Metal foam is a kind of lightweight material with high stiffness-to-weight ratio, high strength-to-weight ratio, novel physical and mechanical properties, such as nearly isotropic, high energy absorption, good sound damping, non-combustibility, easy fabrication to form curved configurations and integrated face-sheets. The metal foam is then selected as the core of the sandwich structure. The steel, aluminum, and metal foam(Titanium foam) are modeled as three- dimensional solid parts. You can see a figure of the assembled parts below

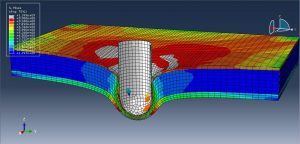

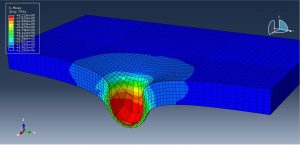

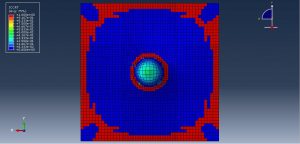

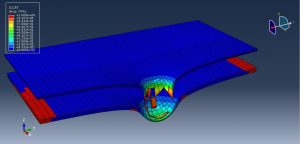

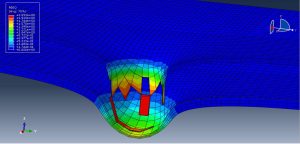

For the steel plate, the material with elastic-plastic(Johnson-Cook) is used. To model damage and failure of the steel plate, Johnson-Cook damage with evolution is implied. Abaqus/Explicit provides a dynamic failure model specifically for the Johnson-Cook plasticity model, which is suitable only for high strain-rate deformation of metals. This model is referred to as the “Johnson-Cook dynamic failure model. Abaqus/Explicit also offers a more general implementation of the Johnson-Cook failure model as part of the family of damage initiation criteria, which is the recommended technique for modeling progressive damage and failure of materials. For the titanium foam, elastic data with Crushable foam plasticity isotropic form with hardening data is used. For the aluminum elastic and Johnson-Cook plasticity and damage are considered. The dynamic explicit step is appropriate for this type of analysis. The general contact algorithm with contact property is assumed as a contact formulation. The perfect contact is considered between the steel and the metal foam, aluminum and metal foam. The fixed boundary condition is assigned to the side surfaces of the panel and initial velocity for the projectile. The mesh should be so fine near the contact zone

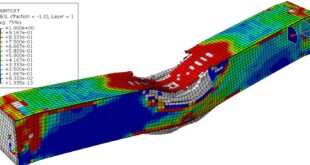

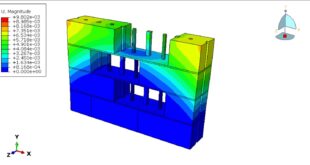

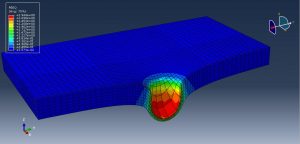

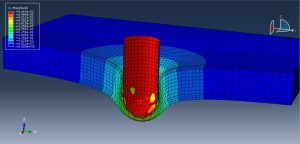

After the simulation all results such as stress, strain, damage, metal foam compression, and….are achievable. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials