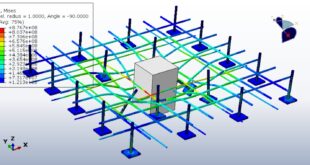

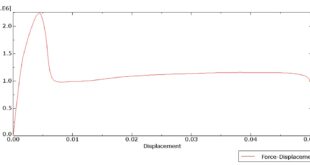

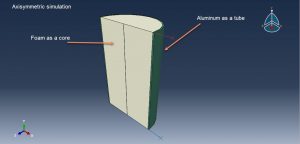

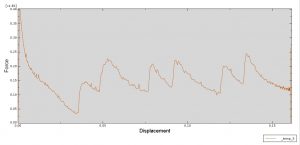

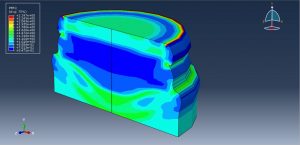

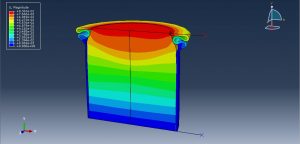

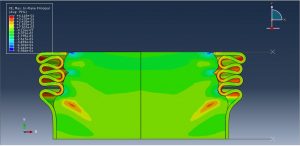

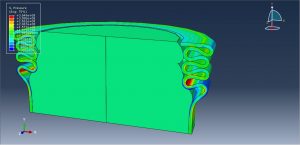

In this simulation, Crushing Simulation of Foam-Filled Aluminium Tubes in Abaqus has been studied. Thin-walled metallic tubes have been applied as energy absorbers because of their progressive buckling under axial compressive loading and the lightness of the structure. According to previous investigations, thin-walled circular tubes can collapse in axisymmetric mode, also known as concertina or ring mode, non-axisymmetric mode, also known as diamond mode, or mixed mode. In which mode a tube crushes largely depends on the geometry of the tube. Energy will be absorbed through the progressive buckling of the structure. In this tutorial axisymmetric dimension is used to model 3 dimensional behavior of aluminum and foam. You can see a figure of the assembled parts at below

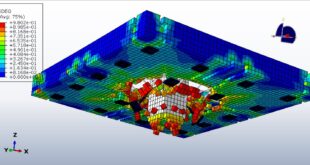

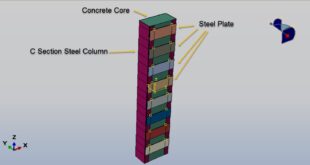

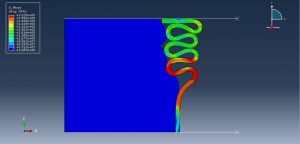

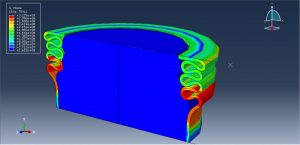

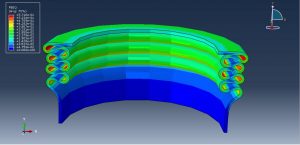

For the aluminum elastic-plastic material and for the foam elastic and crushable foam behavior with hardening is used. The dynamic explicit procedure is appropriate for this type of analysis. The surface to surface contact algorithm to define interaction among all parts and self contact to define the self contact for aluminum and foam are used. The displacement is assigned to the upper rigid plate. The mesh should be fine especially for the aluminum to get proper results. After the simulation, the deformation of aluminum is obvious and all results can be available. You can see some figures for this simulation below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Four Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials